Flowserve CPXV fitted with Mark 3 ASME hydraulics User Manual

Page 32

CPXV with Mark 3 ASME hydraulics ENGLISH 71569291 12-14

Page 32 of 44

flowserve.com

6.11.5 Impeller and casing assembly (threaded

on impeller)

a) Where O-ring option is available, fit a new O-ring

[4610.1] into the impeller, using a small amount of

grease to hold it in place.

High Chrome iron impellers and certain

others do not offer this option).

b)

Assemble impeller [2200] onto the shaft [2100].

c) Tighten the impeller. Use the same method as in

disassembly but rotate in opposite direction. A

few sharp strikes will tighten it to the correct level.

d)

Clean the casing spigot and gasket position

mating surfaces.

e)

Fit a new casing gasket [4590.1].

f)

Install the pump casing with a new casing to

discharge gasket [4590.2].

g)

Install casing hexagon screws [6570.1] to the

specified torques.

h)

Check impeller clearance against original setting,

or process requirement, and adjust as necessary.

(See section 6.7, Setting impeller clearance.)

i)

Check freedom to rotate within pump casing.

6.11.6 Cartridge seal assembly (if fitted)

a)

To set, or reset, a cartridge seal having a PTFE

setting ring-throttle and no separate setting clips,

finger tighten the seal cover stud nuts, then fully

torque up the sleeve screws.

b)

Torque up the seal cover stud nuts.

6.11.7 Coupling, motor and ancillaries

a) Reconnect pump ancillary fittings and piping.

b)

Install pump into sump and connect up remaining

fittings and piping.

c)

Re-check freedom of shaft to rotate by hand.

d)

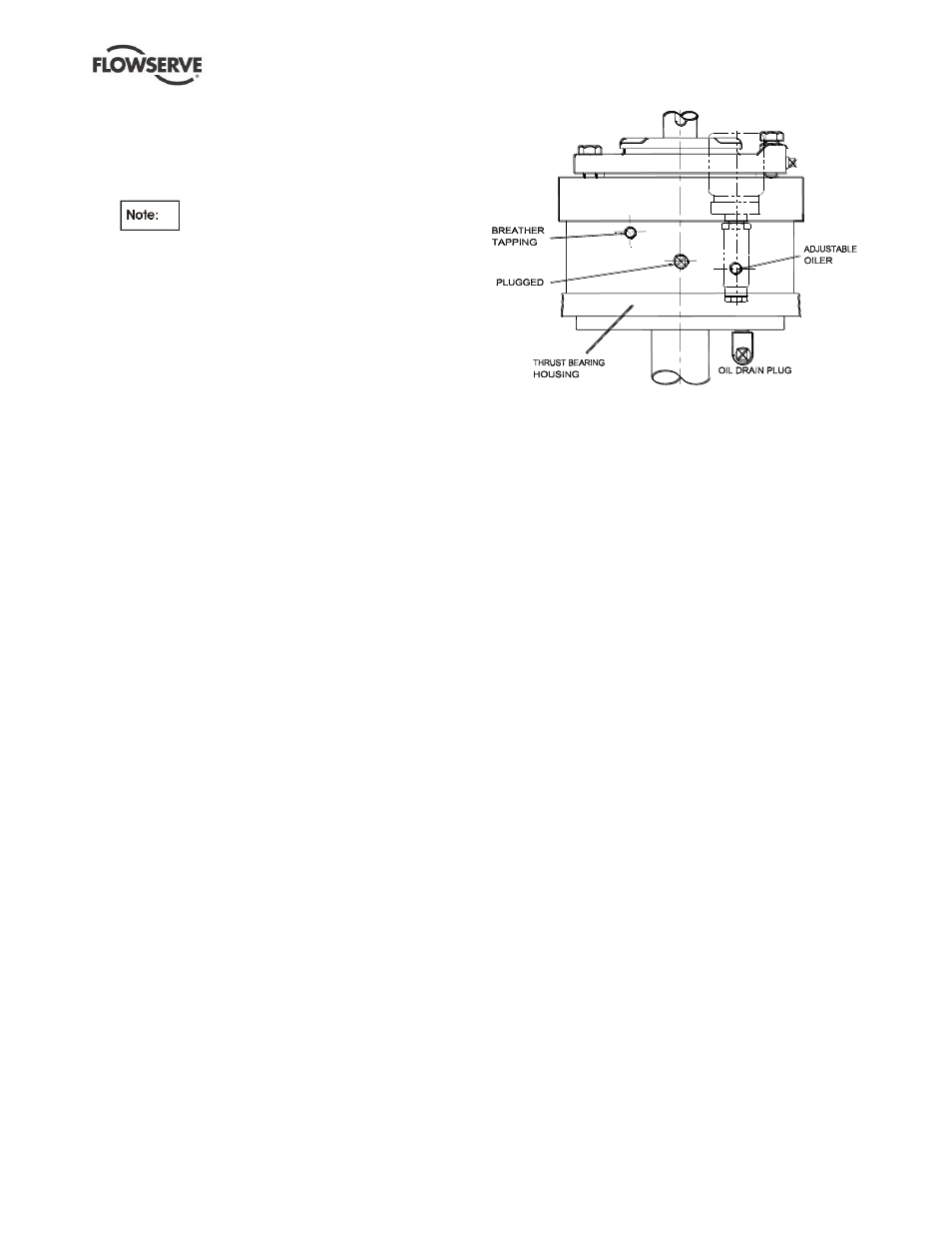

If pump has an oil lubricated thrust bearing, ensure

the oil breather and oiler are assembled in their

correct tappings as shown below and fill with the

correct grade and quantity of oil through the oiler.

e)

Re-install motor (check for correct rotation) and

then fit coupling drive element and guards.

f)

If all is correct continue with the procedure described

under section 4, Installation and section 5,

Commissioning, start-up, operation and shutdown.