Groth 1660A User Manual

Page 9

Page 9 of 16

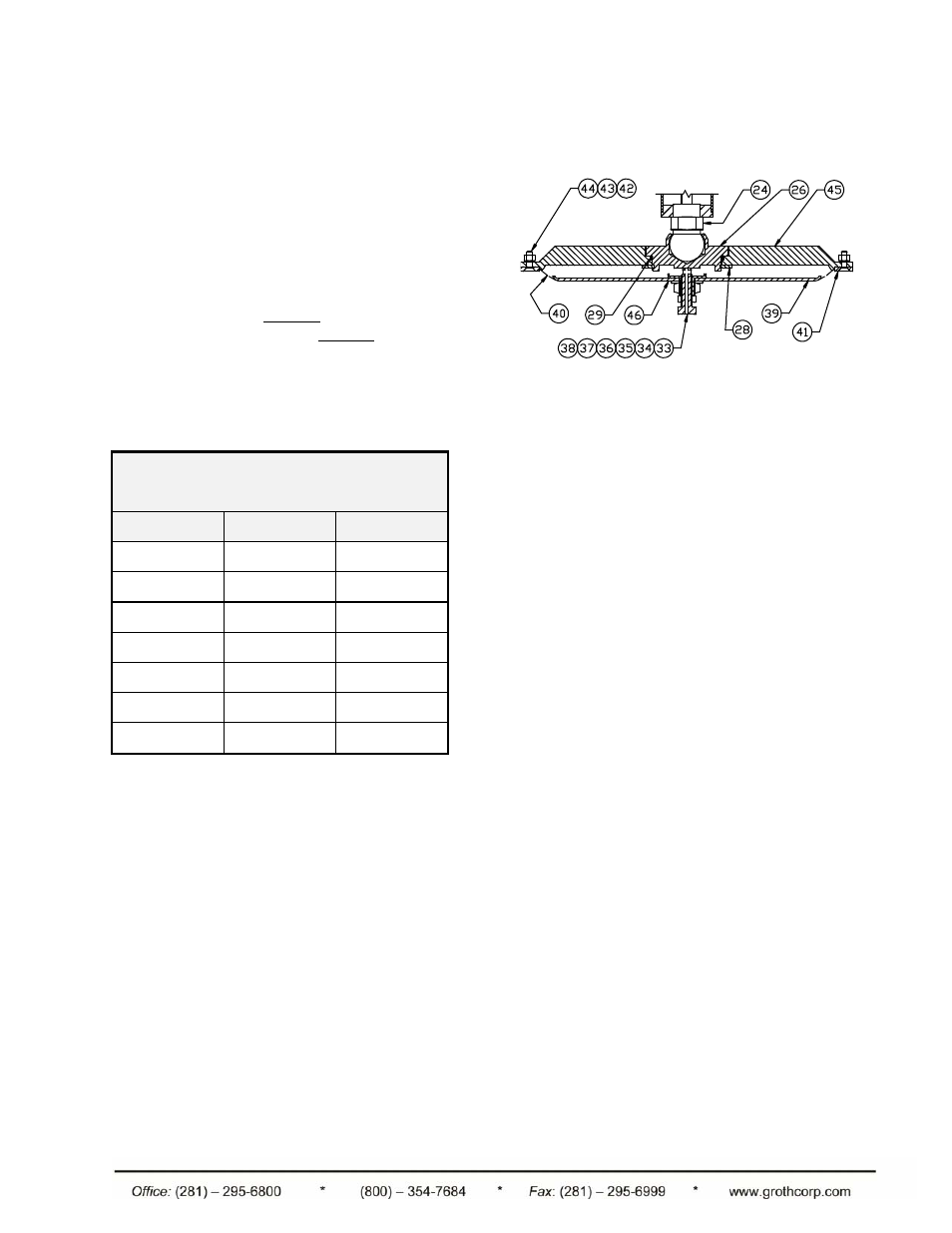

FILM SEAT PALLET

Turn the pallet assembly upside down to

disassemble. If placing in a vise, clamp

against the flats on the swivel ball [24]. Do

not clamp on the socket or it will be deformed

and restrict seat alignment. Loosen the jam

nut [34] and turn the jackscrew [33]

counterclockwise to release tension on the

FEP film [40]. Use an allen wrench to hold the

countersunk screws [42] and loosen the hex

nuts [43] that retain the ring [41]. Remove all

components from the jackscrew assembly

(see Figure 4) and replace the film. Remove

the retaining ring [28] and replace the O-Ring

[29].

To assemble, install the O-Ring [29] in the

pallet counterbore and insert the swivel socket

[26]. Replace the retaining ring [28]. Do not

expand the retaining ring excessively.

Table 6

FEP Seat Film Dimensions

SIZE

O.D.

HOLE DIA.

2” 4.50”

0.38”

3” 5.50”

0.38”

4” 6.50”

0.38”

6” 8.50”

0.44”

8” 10.63”

0.44”

10” 12.63” 0.62”

12” 14.63” 0.62”

The FEP film [40] is provided at least 3/4”

larger than the outside diameter of the film

seat ring [41]. This excess material is

required for handling at assembly. Place the

film on a clean flat surface and punch a hole

in the center (see Table 6) to provide

clearance for the jackscrew bushing [35].

Install the jackscrew bushing [35] through the

film tension plate [39]; as shown in Figure 4.

Lay the film [40] over the plate [39], then the

fluoropolymer washer [46]; flat washer [38];

belleville washer [37]; and tighten the jam nut

[36] while holding the jackscrew bushing with

a wrench. Tighten until the belleville washer

is flat; do not over-tighten as the FEP film can

be damaged or cut at the washer O.D. Use

care in handling the film at all stages of

assembly.

Screw the jam nut [34] completely onto to the

jackscrew [33] and thread the jack screw into

the jackscrew bushing [35] until the tip

extends slightly through the opposite end (hex

side).

Figure 4: Film Pallet Assembly

Position the film sub-assembly on the face of

the pallet with the tip of the jackscrew [33] in

the counterbore of the swivel socket [26].

Hold the film so it is taut and wrinkle free.

Align the bolt holes of the seat ring [41] and

pallet [45] and press the parts firmly together,

clamping the film securely.

Punch four holes at 90

apart through the film

and insert the socket head screws [42]

through the ring and plate. Install the lock

washers [44] and hex nuts [43] and tighten

using an allen wrench to hold the screws.

Complete the assembly by punching the

remaining holes and install the screws, lock

washers and hex nuts.

After all fasteners are tightened, turn the

jackscrew [33] clockwise to tighten the film

until the slope is approximately 15

. Do not

over-tighten, as it is possible to bend the

tension plate [39] or tear the film. Tighten the

jam nut [34] to lock the jackscrew. Using a

sharp knife, trim the excess film at the O.D. of

the ring [41].

Carefully set the film seat pallet assembly

onto the valve body seat. Check the gap

between the bottom of the film seat ring [41]

and the top surface of the body seat; it should

be between 1/32” and 1/16”. If there is

insufficient clearance, the film should be

retensioned. Carefully lift the assembly out of

the valve and loosen the jam nut [34] on the

jackscrew two or three turns. Rotate

jackscrew clockwise as required to tension

film and then retighten the jam nut [34].

Lower the pallet assembly into the valve and