Troubleshooting guide, Preventive maintenance, Recommended spare parts – Groth 3011L User Manual

Page 11: Table 6 – soft goods kits

10

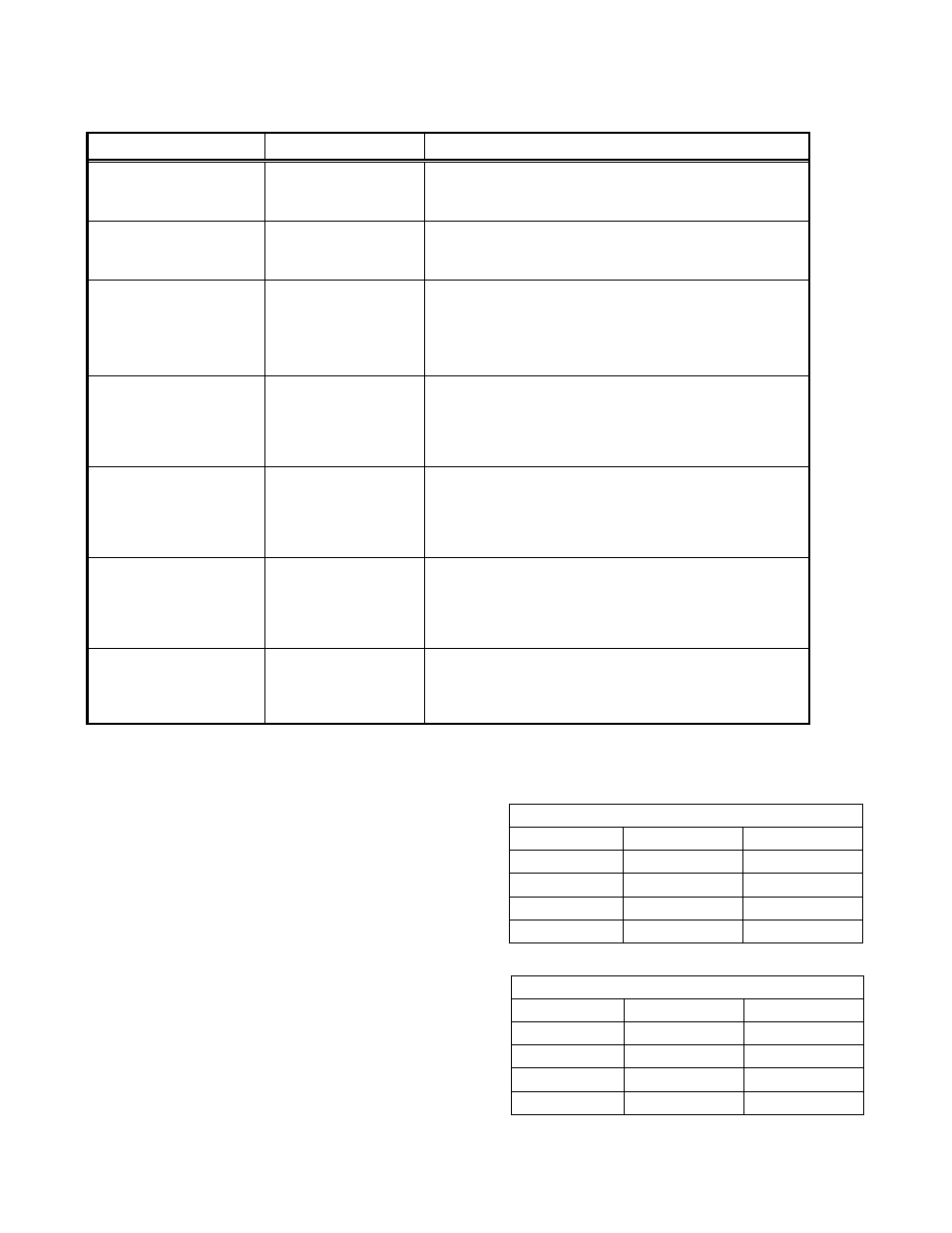

TROUBLESHOOTING GUIDE

PROBLEM

INSPECTION

SUGGESTED CORRECTIVE ACTION

Gas flowing at tank

pressure above

specified set point.

Flow indicator in

blanket gas line.

Damaged seat, O-Ring or diaphragm or pressure setting

too high. If original pressure setting has not been

disturbed, remove regulator and repair.

Gas not flowing at tank

pressure below

specified set point.

Flow indicator in

blanket gas line.

Damaged spring or pressure setting too low. If original

pressure setting has not been disturbed, remove

regulator and repair.

Gas leaking from upper

vent or bonnet

flange.

Soap bubble test and

joining surface or

emission

indication near the

regulator.

Damaged upper piston diaphragm. Remove regulator from

tank and replace diaphragm. Diaphragm installed

incorrectly. Reinforcement fabric must be opposite to

pressure (see page 12).

Blanket gas leaking from

lower body seal or

actuator housing

vent.

Soap bubble test at

joining surface or

emission

indication near the

regulator.

Damaged lower piston diaphragm. Remove regulator from

tank and replace diaphragm. Diaphragm installed

incorrectly. Reinforcement fabric must be opposite to

pressure (see page 12).

Process vapor leaking

from actuator

housing flange or

vent.

Soap bubble test at

joining surface or

emission

indication near the

regulator.

Damaged actuator diaphragm or loose housing bolts.

Tighten bolts or remove regulator from tank and

replace diaphragm.

Tank pressure above or

below specified

operating range

during pump out or

pump in.

Observe tank pressure

indicator during

pumping

operations.

Excess or insufficient blanket gas flow. Check flow orifice

orientation. Refer to Tables 4 & 5 for flow capacity

data. Check gas supply pressure. Remove and repair

regulator if other conditions are correct.

Tank pressure or vacuum

exceeds vent

settings during pump

out or pump in.

Observe tank pressure

indicator during

pumping

operations.

Pressure/vacuum relief vent not functioning or not sized

properly. Inspect and repair or replace as necessary.

PREVENTIVE MAINTENANCE

Periodically, while in service, examine the regulator for

leakage at bolted connections, adjusting screws, etc. Test

for blanket gas or process vapor emissions from vent caps.

RECOMMENDED SPARE PARTS

The following spare parts should be stocked for maintenance

purposes:

Spring [34]; See Table 3 for the correct part number.

Vent [24]; part number 10064003

Soft Goods Kit; See Table 6 for the correct part number.

When ordering spare parts, include model and serial number

of regulator, pressure setting, and required material for soft

goods.

TABLE 6 – SOFT GOODS KITS

1/2" BGR

Elastomer 3011L

3011H

Buna-N KS3011L05B

KS3011H05B

FFKM KS3011L05C

KS3011H05C

EPDM KS3011L05E

KS3011H05E

FKM KS3011L05V

KS3011H05V

1" BGR

Elastomer 3011L

3011H

Buna-N KS3011L01B

KS3011H01B

FFKM KS3011L01C

KS3011H01C

EPDM KS3011L01E

KS3011H01E

FKM KS3011L01V

KS3011H01V