Kemppi FastMig Pulse 350 User Manual

Page 10

EN

2.5.4 Welding and earth return cables

Kemppi always recommend the use of high quality copper cables with a suitable cross-

sectional area. Cable size should be selected depending on the intended welding application.

50mm2 copper welding cables may be used for low duty work in basic or Synergic 1-MIG.

However when using Pulse MIG/MAG process, and or longer cables, and or higher welding

power, voltage loss increases, and therefore smaller cross sectional interconnecting power and

return cables will restrict the welding performance of your machine.

• FastMig Pulse 350 – 70 to 90 mm²

• FastMig Pulse 450 – 70 to 90 mm²

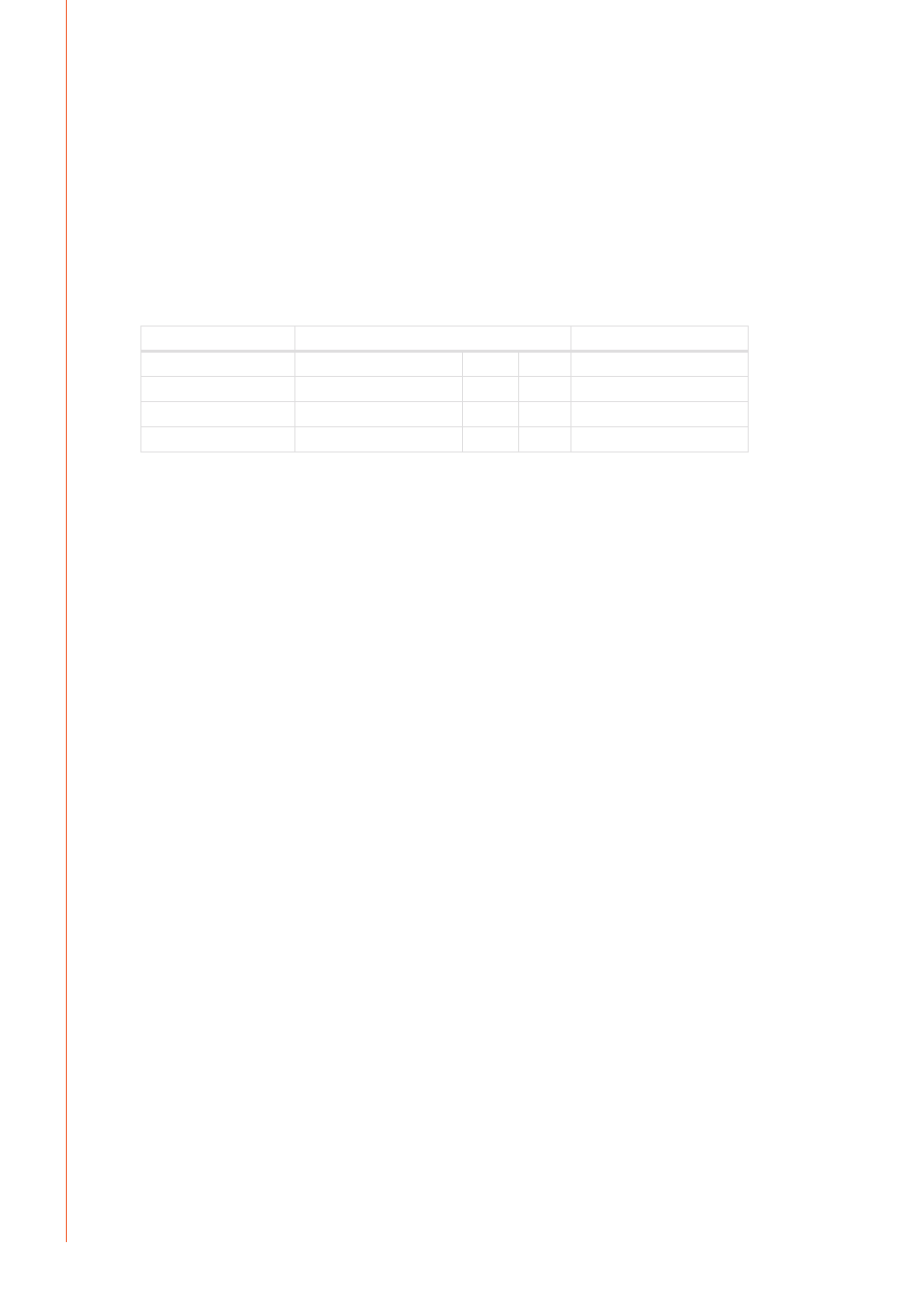

The enclosed table shows typical load capacities of rubber insulated copper cables, when

ambient temperature is 25 °C and the cable temperature is 85 °C.

Cable

Duty cycle ED

Voltage loss / 10 m

100 %

60 %

30 %

50 mm²

285 A

370 A

520 A

0.35 V / 100 A

70 mm²

355 A

460 A

650 A

0.25 V / 100 A

95 mm²

430 A

560 A

790 A

0.18 V / 100 A

Do not overload welding cables due to voltage losses and heating.

NOTE!

Always check the serviceability of the earth return cable and clamp. Ensure the metal

surface to which the cable is connected is clean from metal oxide or paint. Check the connector to

the power source is fastened correctly.

2.5.5 Interconnection with wire feeder

Kemppi provide a choice of interconnection cable sets for different environments. Only

materials that meet the demands of Kemppi's international markets are used in their

construction.

Used correctly, Kemppi cables sets ensure high welding performance and serviceability.

Before use, always ensure the cable set is in good condition and that connectors are correctly

fastened. Loose connections reduce welding performance and may result in damage to

connectors due to heating effects.

For correct connection and configuration of cable sets, please refer to schematic drawings:

2.5.1 and 2.5.2

NOTE!

FastMig 350/450 power sources are designed to be used ONLY with MXF wire feed units.

FastMig Pulse 350, 450

8