Yaskawa A1000 AC Drive Quick Start User Manual

A1000 ac drive quick start procedure (olv), Page 1 of 2, Check motor direction (motor uncoupled from load)

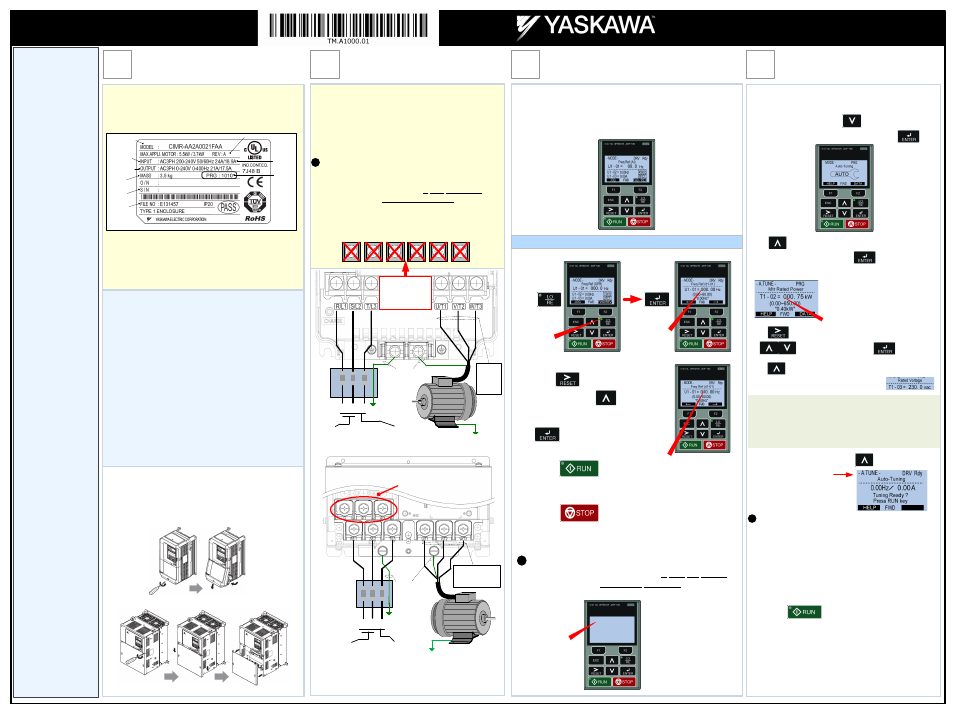

Step

1

A1000 Model

Identification and Mounting

Connect Motor and

Line Power

Step

2

Step

3

Check Motor Direction

(Motor uncoupled from Load)

Step

4

Rotational Auto-tuning

(De-couple Motor from Load)

The following

procedure is a

supplement to

other

documentation

supplied with this

equipment and will

guide the user in

properly wiring the

A1000 and motor.

It will also show

the user how to

configure the

A1000 in open

loop vector mode

for a general

purpose

application.

DANGER!

Improper wiring

can and will cause

bodily harm as well

as damage to the

equipment.

When installing the

system, be sure to

follow good wiring

practices and all

applicable codes.

Ensure that the

mounting of

components is

secure and that the

environment, such

as extreme

dampness, poor

ventilation, etc. will

not cause system

degradation.

Please read this

cheat sheet and

other

documentation

provided with the

A1000 thoroughly

before attempting

any installation.

Motor Rotation Test

In this step the motor is checked for proper direction and operation.

This test is to be performed solely from the digital operator. Apply

power to the A1000 after all the electrical connections have been

made and protective covers have been re-attached. At this point,

DO NOT RUN THE MOTOR, the Digital Operator should display as

shown in

Fig. 3

.

Fig. 3

Digital Operator

Use precaution, and

refer to

Fig.1 or 2,

swap

any

two

of the

three

output leads to the motor

(U/T1, V/T2 and W/T3).

After the wiring change,

repeat

Step 3

and

recheck motor direction.

After the power has been turned OFF, wait at least five minutes

until the charge indicator extinguishes completely before touching

any wiring, circuit boards or components.

DANGER!

If motor rotation is not correct, then either reverse “Phase Order”

using parameter b1-14 or power down the drive, wait five minutes

and swap 2 motor leads.

!

Next, press to move the cursor one

position to the right and to increase the

frequency reference (d1-01) to 10.00 Hz.

Press to save frequency reference.

Next, press on the Digital Operator. The motor

should now be operating at low speed running in the correct

forward (clockwise) direction.

Next, press on the Digital Operator.

Digital Operator

turned off.

First Digit

Flashing

Press

Green LED

turns on.

10.00 Hz

In this step the A1000 is setup for use with the motor. Make sure

all protective covers have been re-attached then apply power to

the A1000. D

DO NOT RUN THE MOTOR.

From the main reference press once until the Digital

Operator shows the Auto-Tuning menu then press

Press once until the Digital Operator shows parameter

T1-02 Mtr Rated Power then press

Digit Flashing

Press to select the digit you would like to change and

use to adjust value and press to save.

Enter Motor Power in kW (Kilowatt)

Motor HP to kW = HP x 0.746

Example: 10HP = 10 x 0.746 = 7.46 kW

T1-04 Rated Voltage (e.g. 230 V, 460 V)

T1-04 Rated current (e.g. 11.0 A, 22.0 A)

T1-05 Rated Frequency (e.g. 60.0 Hz)

T1-06 Number of Poles (e.g. 4 Poles)

For standard AC motors use

the default setting for motor

base frequency (60Hz), motor

poles (4) and motor rated

speed.

T1-07 Rated Speed (e.g. 1750 rpm)

Press to select the next parameter and follow the same

procedure described above to adjust its value.

Warning! Sudden movement hazard. The A1000 and

motor may start unexpectedly during Auto-Tuning.

Warning! Electric Shock Hazard. High voltage will be

supplied to the motor when stationary Auto-Tuning is

performed. Do not touch the motor during auto-tuning.

Notice: Auto-Tuning will not function properly when a brake

is engaged on the load. Ensure the motor shaft can freely

rotate. Never perform an Auto-Tune with motor connected

to a load.

!

After setting parameter T1-07 press to select the

Auto-Tuning start command.

Next, press on the Digital Operator. The A1000

will now start the Auto-tuning procedure.

The display will show message “

Tune Successful” when the

Auto-Tuning procedure has been successfully completed.

Please reference the A1000 User Manual or repeat the

procedure again if the display shows an error message.

Page 1 of 2

WARNING DO NOT CONNECT ANY OF THE

FOLLOWING TERMINALS TO EARTH GROUND

B1

B2

-

+1

+2

+3

NOT USED

Fig.1 & 2

below show the electrical connections for the

input power and motor terminals for various A1000 models.

Select the proper diagram for the model you are installing

(see Step 1).

WITH POWER OFF

make the appropriate

connections.

Make sure to follow good wiring practices and all applicable

codes. Ensure that the equipment is grounded properly as

shown in fig. 1

DANGER!

LETHAL VOLTAGES ARE PRESENT- Before

applying power to the A1000, ensure that the terminal cover

is fastened and all wiring connections are secure. After the

power has been turned OFF, wait at least five minutes until

the charge indicator extinguishes completely before touching

any wiring, circuit boards or components.

!

Make sure the A1000 has been properly sized for single phase input

power. For best performance, the drive input supply voltage must be at

least equal to or greater than the motor rated voltage.

3Ø Induction

motor

Connect

frame to

ground

Input

Protection

(Fuse or Circuit

Breaker)

To change direction of motor

rotation swap any

two of the

three motor leads

(See Step 2)

Fig. 2 Input Power and Output Motor Electrical Connections for

Models: 2_0110 & Larger and 4_0058 & Larger

(R/L1)

(S/L2)

(T/L3)

(U/T1)

(V/T2)

(W/T3)

Connect to

chassis

ground

Use L1, L2, L3 for

3Ø Input Power

L1 L2 L3

Use L1, L2 for

1Ø Input Power

*

BUS TERMINALS:

DO NOT CONNECT TO GROUND

Use L1, L2, L3 for

3Ø Input Power

To change

direction of

motor rotation

swap any

two

of the

three

motor leads

(See Step 2)

Fig. 1 Input Power and Output Motor Electrical Connections for

Models: 2_0004 - 2_0056, 4_0002 - 4_0044 and 5_0003 - 50011

Use L1, L2 for

1Ø Input Power

3Ø Induction

motor

Connect

frame to

ground

Input

Protection

(Fuse or Circuit

Breaker)

L1 L2 L3

(R/L1)

(S/L2)

(T/L3)

(U/T1)

(V/T2)

(W/T3)

Connect to chassis

ground

*

DC Bus terminals

location varies by

model.

*

To make sure you received the correct model, it is essential to

verify the A1000 nameplate with your order and make sure the

A1000 has the correct rating so it can be used with your motor.

Please check the nameplate information as shown in the

example below.

·

Check that the available power will meet the

input power

requirements.

·

Ensure that the

output power from the A1000 is

compatible with the motor requirements.

Mounting the A1000

·

In the case of systems with more than one A1000, follow

the above procedure for each A1000 and motor.

The mounting of the A1000 is extremely important regarding

environment and accessibility. Depending on your system,

there are various models available and the mounting

dimensions (footprint) may be different. Because the

mounting procedure is fairly extensive, it is beyond the scope

of this document; the user is referred to the A1000 Technical

Manual (Document No. SIEP C710616 41) received with the

A1000,

Section 2.2 Mechanical Installation. Match the model

that you received and follow the procedure described in the

manual to ensure a safe and functional installation. In cases

where the system has more than one A1000, refer to the

proper clearances required for adequate ventilation.

Please

pay particular attention to:

·

The clearances to be maintained around the enclosure

for adequate ventilation.

·

The environmental specifications such as avoiding

excessive dampness, extreme temperatures, chemical

exposure, corrosive areas, etc. to avoid damage to the

equipment and to maintain safety.

Removing and Attaching the Terminal Cover

Improper removal of the A1000 terminal cover as well as

front cover can cause extensive damage to the A1000. To

avoid damage to these items, please pay particular attention

to the A1000 Technical Manual,

Document No. SIEP C710616 41, Section 3.5, R

Removing

and Attaching the Terminal Cover.

Open Chassis

NEMA 1

Drive Model

Number

Input Power

Rating

Output Power

Rating

Serial

Number

UL File

Number

Drive Spec Number

Weight

Software

Version

Normal /

Heavy Duty

Amps

A1000 AC Drive

Quick Start Procedure (OLV)