LowFlow Mark 708SH Series Short Pattern 1/4 User Manual

I & m mark 708, Ideal installation, Start-up procedure

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

[email protected] • www.lowflowvalve.com

I & M Mark 708

Installation & Maintenance Instructions for

Mark 708 & 14M Actuator and Motor Valve

Warning: Jordan LowFlow Control Valves must only be used, installed and repaired in accordance with these

Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In

the event of leakage or other malfunction, call a qualified service person; continued operation may cause system

failure or a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before

disassembling a valve, be sure to release all spring tension.

Please read these instructions carefully!

Your Jordan LowFlow Valve product will provide you with

long, trouble-free service if it is correctly installed and

maintained. Spending a few minutes now reading these

instructions can save hours of trouble and downtime

later. When making repairs, use only genuine Jordan

LowFlow Valve parts, available for immediate shipment

from the factory.

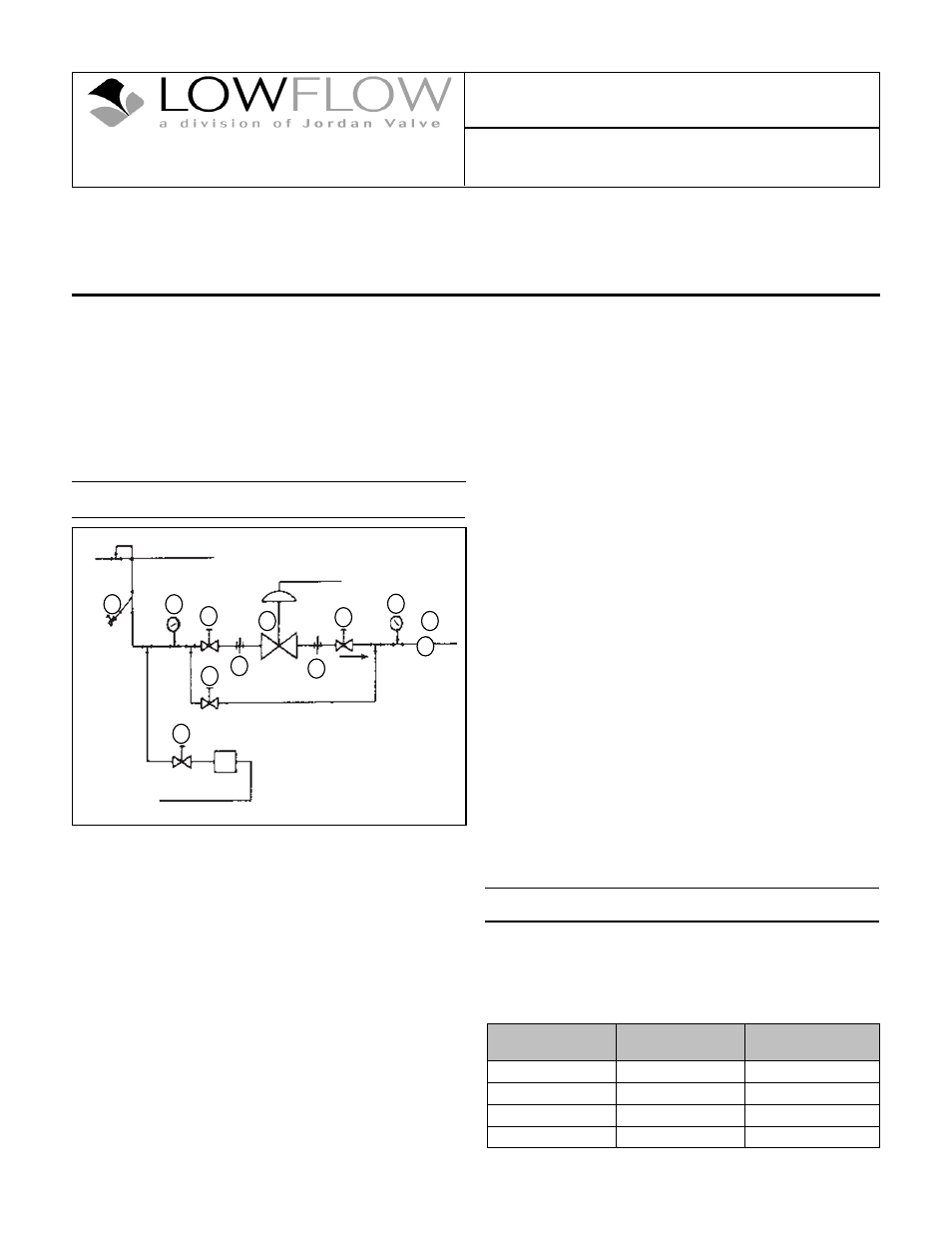

Ideal Installation

To control very low flow rates, Mark 708 control

1.

valves are often provided with trims having very

small clearances. To keep this trim functioning

properly, it is essential that the fluid flowing through

the valve be clean.

To protect the valve from grit, scale, thread chips

2.

and other foreign matter, ALL pipelines and piping

components should be blown out and thoroughly

cleaned before the installation process begins.

Shutoff valves, pressure gauges, and by-pass piping

3.

should be installed as indicated in the Installation

Schematic to provide easier adjustment, operation

and testing.

A line strainer should be installed on the inlet side

4.

of the valve to protect it from grit, scale, and other

foreign matter. A 0.033 perforated screen is usually

suitable for this purpose. Line strainers are avail-

able from Jordan Valve.

For best control, 3’ 0” straight sections of pipe

5.

should be installed on either side of the valve.

In preparing threaded pipe connections, care

6.

should be exercised to prevent pipe-sealing com-

pound from getting into pipelines. Pipe sealing

compound should be used sparingly, leaving the

two end threads clean. Jordan uses, and recom-

mends, thread sealer Teflon ribbon.

The flow arrow on the valve body must be pointed

7.

in the direction of the flow. Ideally the valve should

be installed in the highest horizontal line of pip-

ing to provide drainage for inlet and outlet piping,

to prevent water hammer, and to obtain faster re-

sponse.

If possible, install a relief valve downstream from

8.

the valve. Set at 15 psi above the control point of

the valve.

In hot vapor lines, upstream and downstream pip-

9.

ing near the valve should be insulated to minimize

condensation.

Evaluate inlet and outlet pipe friction losses and ve-

10.

locities to decide when smaller outlet piping might

cause excessive back pressure. When required, a

standard tapered expander connected to the outlet

of the valve is recommended.

Where surges are severe, a piping accumulator is

11.

recommended.

On steam control applications, install a steam trap

12.

with sufficient capacity to drain the coil or condens-

er. Be sure to have a good fall to the trap, and no

backpressure. Best control is maintained if the coil

or condenser is kept dry.

Start-Up Procedure

Be sure that the action of the control valve and of

1.

the controller are such that you achieve the desired

results. The action can be changed if needed us-

ing the instructions shown in “Reversing Action”.

Increase in pressure

or temperature must:

And the action of

the valve is:

Then the action of the

controller must be:

Close Valve

Air to Close (direct)

Direct

Close Valve

Air to Open (reverse)

Reverse

Open Valve

Air to Close (direct)

Reverse

Open Valve

Air to Open (reverse)

Direct

1. Shut off Valve

2. Pipe Union

3. Strainer and Drain Valve

4. Pressure Gauge

5. Mark 708DCV

6. Relief Valve

3

R

6

4

1

5

1

4

2

1

2

1