Label rewinding, External halt control, Maintenance – QuickLabel RW-2 User Manual

Page 2

(2) Slide the shaft and flange assembly onto the RW motor shaft allowing for

clearance to the RW-2 chassis and motor screws. Tighten the Allen screw to

secure the shaft and flange assembly until it is snug, but not too tight.

(3) Set the unit in place near the label exit path of the printer.

CAUTION: AVOID ACCIDENTS. CHOOSE ONLY A

STURDY SURFACE ON WHICH TO SET THE RW UNIT.

(4) The RW-2 and RW-8 are bi-directional. They can wind labels in either direction.

Verify that the

Direction Switch

on the Control Panel is in the

Off

position.

(5) Connect the power lead from the Power Supply unit to the power Input Jack on

the back panel of the Drive Unit. Plug the AC Power Cord into the Power Supply

and into an appropriate AC power outlet.

The Rewinder is now ready for use.

LABEL REWINDING

(1) Place the

Direction

Switch on the Control Panel in the center

OFF

“0”

position.

(2) Slide an empty 3-inch (76-mm) label core over the Core Holder (Core Chuck)

until the core is against the inner flange plate.

(3) If desired, slide the outer Flange Plate (with the center Nylon hub) over the Core

Chuck and up against the label rewind core. Tighten the Core Chuck Lock Knob

clockwise to secure the core and outer Flange Plate.

(4) Feed the label web from the printer and secure it to the take-up roll core with

masking tape. Manually rotate the take-up reel a couple of turns.

(5) Check that the Rewinder Unit is square with the printer.

(6) Place the Rewinder

TORQUE RANGE

Switch in the

NORMAL (REWIND)

position.

NOTE: YOU CAN USE THE HIGH (SLIT) POSITION FOR LABEL SLITTING OR

WHEN REWINDING LARGE DIAMETER ROLLS.

(7) Rotate the

TORQUE ADJUST

Control Knob to the minimum position (fully

counter-clockwise).

(8) Place the RW-2

DIRECTION

Switch in the position desired to run left or right.

(9) Start the printer and adjust the

TORQUE ADJUST

Knob for the desired take-up

tension. Use only the minimum torque setting needed to rewind labels properly.

Excessive torque might pull the labels too hard and cause the printer to lose registra-

tion.

(10) When rewinding is finished, place the

DIRECTION

switch in the

OFF

“0”

position. Turn the Core Chuck lock lever counterclockwise to release the outer

Flange and label roll from the unit.

EXTERNAL HALT CONTROL

QuickLabel Systems has provided an

EXTERNAL HALT CONTROL

to allow an

external device to optionally command the Rewinder to start or stop. If an external

unit, such as the printer, label slitter, etc. opens the control circuit, the Rewinder will

immediately disconnect power to the motor and apply braking.

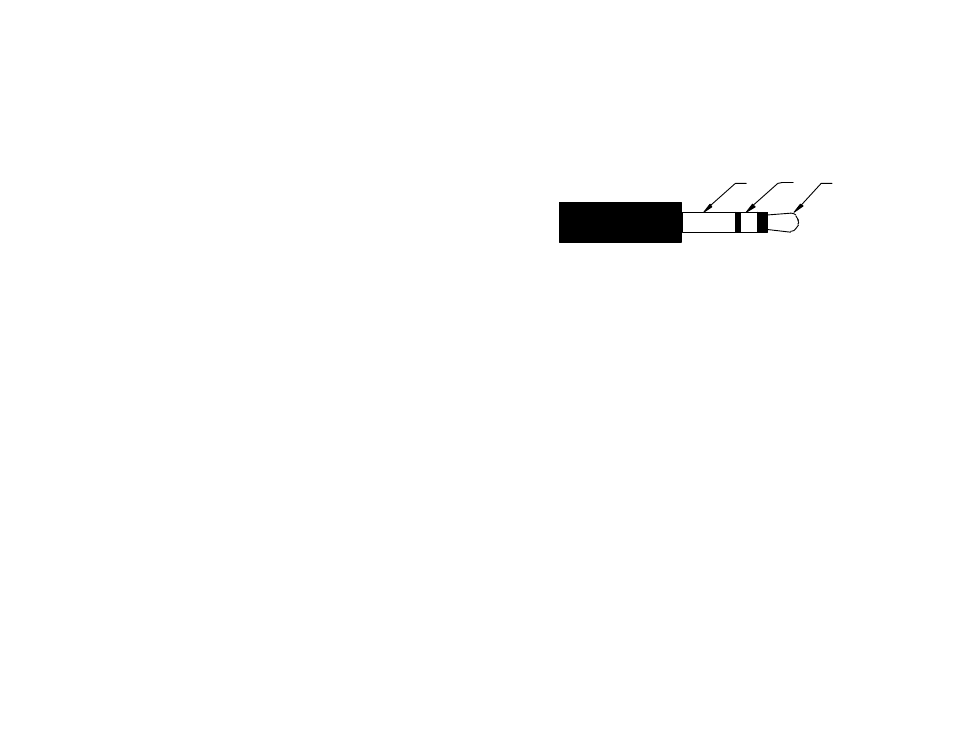

Use a 3.5 mm dual circuit plug and cable plugged into the

EXTERNAL HALT

CONTROL

Jack. The Rewinder

Control Plug

connections are described below.

3.5mm External Halt Control Plug (dual circuit)

CONTACTS 2 & 3 OPEN: Rewinder HALTS

CONTACTS 2 & 3 CLOSED: Rewinder RUNS

1 = No connection (Not Used)

2 = Normally Closed (NC) contact return

3 = Normally Closed (NC) contact

MAINTENANCE

Your Label Rewinder requires no periodic or preventative maintenance.

2

3

1