9 specific machine performance, 2 transport and storage, 1 consignment receipt and unpacking – Flowserve MN User Manual

Page 9

MN USER INSTRUCTIONS ENGLISH 71569189 11/04

Page 9 of 49

®

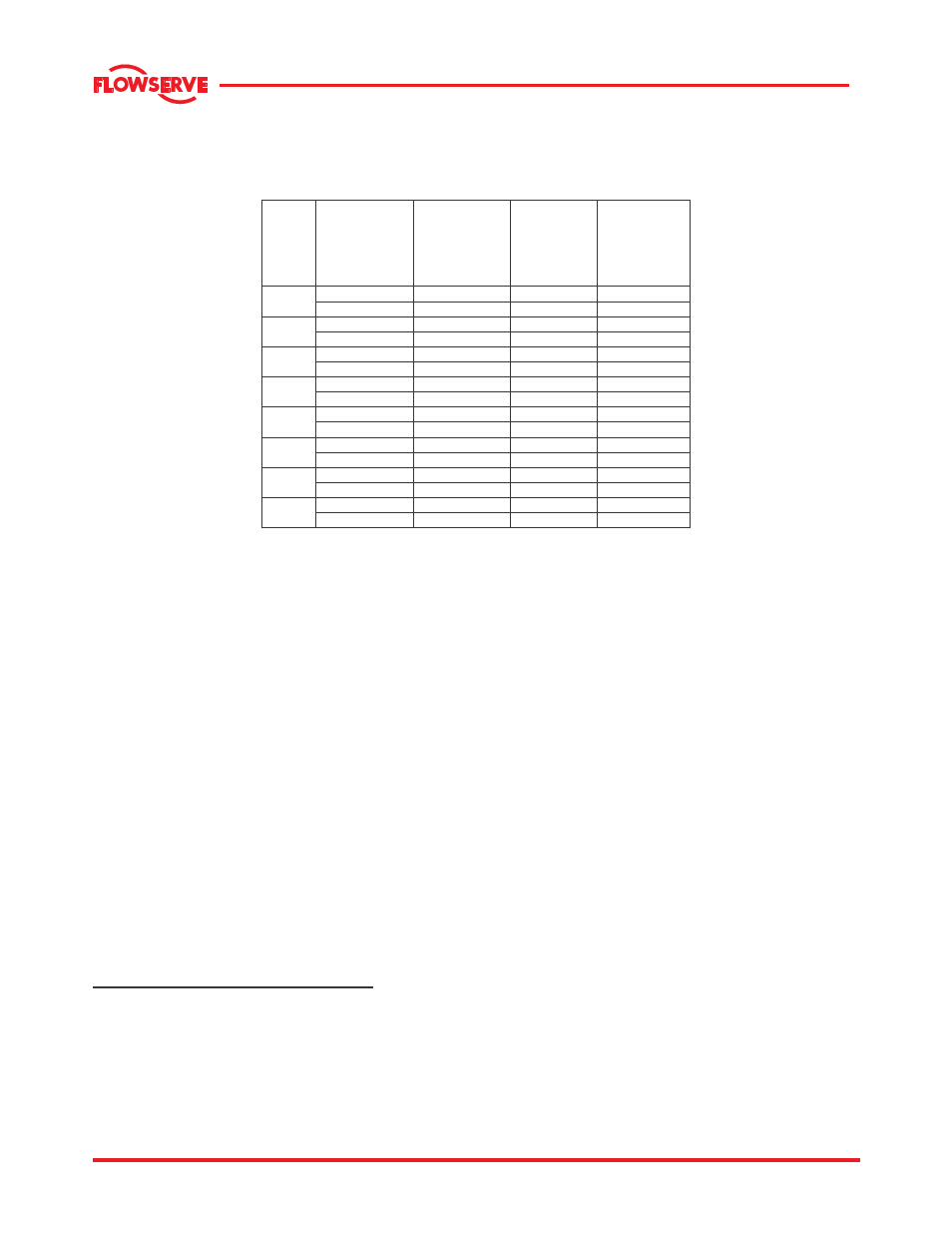

1.8.1 Typical sound levels for MN pumps

Pump noise level is dependent on a number of factors such as: the type of motor fitted, the operating capacity,

pipe work design and acoustics of the building. Typical sound pressure levels measured in dB, and are A-

weighted.

Motor

Frame

Size.

NEMA

RPM

Motor Only

Sound

Pressure

(dBA )

Pump only

Sound

Pressure

(dBA )

Combination

of pump and

motor

Sound

pressure

(dBA)

1800

60.0

65

70

180

1200 & slower

55.0

55

63

1800

60.0

65

69

210

1200 & slower

55.0

56

63

1800

70.0

77

77

250

1200 & slower

60.0

68

69

1800

70.0

77

77

280

1200 & slower

60.0

68

69

1800

65.0

77

77

320

1200 & slower

65.0

69

69

1800

65.0

77

78

360

1200 & slower

65.0

68

69

1800

70.0

77

78

400

1200 & slower

65.0

68

69

1800

70.0

77

78

440

1200 & slower

65

68

69

Sound pressure values indicated for the motor are extracted from typical motor manufacturer’s data at no load

conditions and are not guaranteed. They may vary depending on the type of motor, enclosure used, and the

manufacturer. The sound pressure values for the pump are estimated levels in free field measured 1 meter from the

nearest major pump surface and at a height of 1.5 meters above the floor. using speed, flow rate, motor horsepower,

number of impeller vanes, and other variables. Therefore values indicated are for reference only and could exceed

the estimated values by as much as 8~10 dBA depending upon factors such as installed conditions, building

acoustics, foundation, piping, operating conditions, surrounding machinery. It is highly recommended to take actual

field measurement of sound pressure values, apply enclosures and safety measures mandated by the local

authorities and prevailing safety regulations. For all other pump and motor frame size combinations, the sound

levels have to measured and safety measures have to be adopted.

For units driven by equipment other than electric motors or units contained within enclosures, see the

accompanying information sheets and manuals.

1.9 Specific machine performance

For performance parameters see section 1.5,

Duty

conditions

. When the contract requirement specifies

these to be incorporated into User Instructions these

are included here. In cases where performance data

has been supplied separately to the purchaser these

should be obtained and retained with these User

Instructions, if required.

2 TRANSPORT AND STORAGE

2.1 Consignment receipt and unpacking

Immediately after receipt of the equipment it must be

checked against the delivery and shipping

documents for its completeness and that there has

been no damage in transportation.

Any shortage and or damage must be reported

immediately to Flowserve Pump Division and

received in writing within one month of receipt of the

equipment. Later claims cannot be accepted.

Check any crate, boxes, and wrappings for any

accessories or spare parts that may be packed

separately with the equipment or attached to the

sidewalls of the box or equipment.

Each product has a unique serial number. Check

that this number corresponds with that advised and

always quote this number in correspondence as well

as when ordering spare parts or further accessories.