Stainless steel bevel cutting, H35 and n, Plasma / n – Hypertherm HPR800XD Auto Gas Rev.2 User Manual

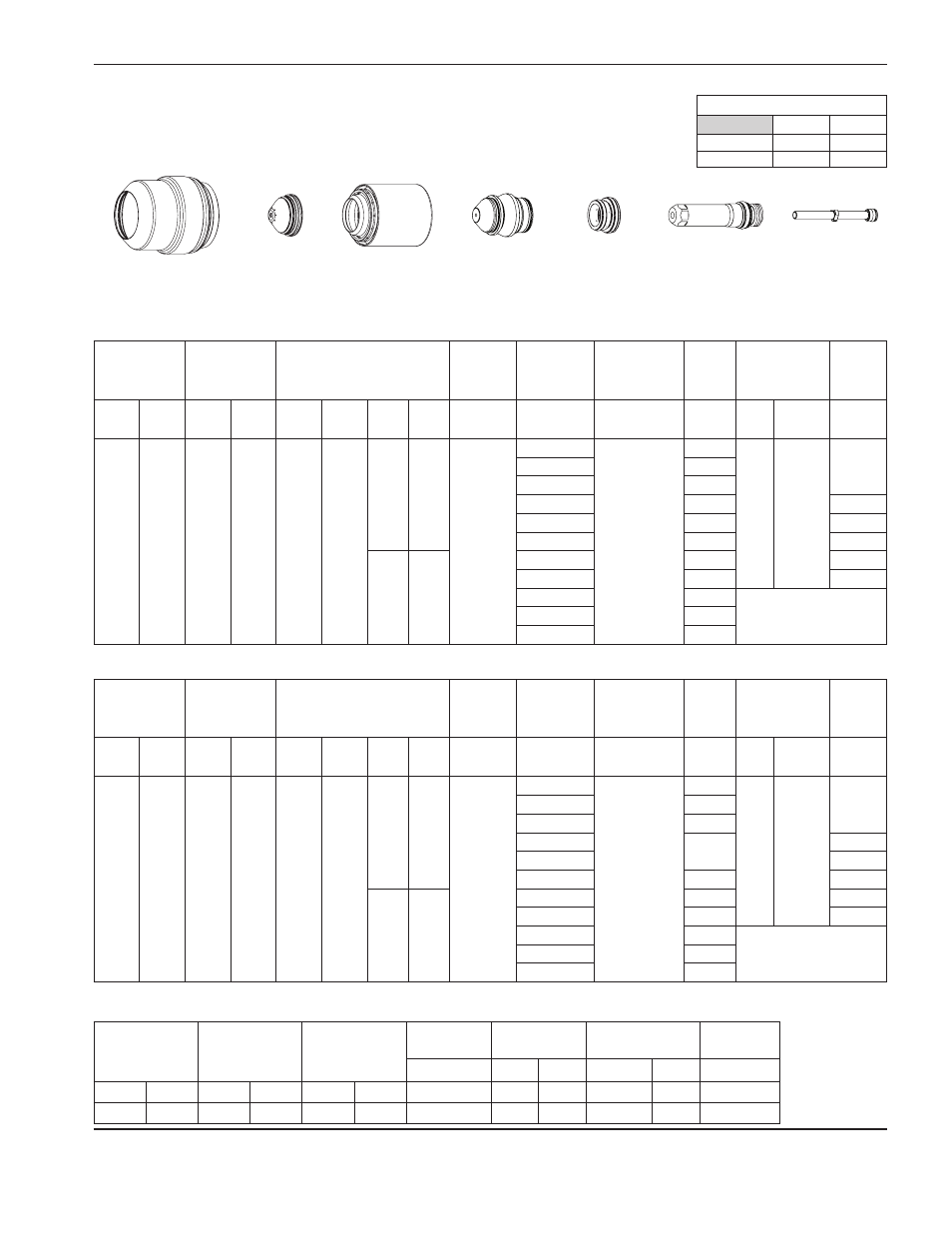

Page 185: Shield 260 a, Metric english, Marking

OperatiOn

HPR800XD Auto Gas –

806500

4-79

Stainless steel bevel cutting

H35 and N

2

Plasma / N

2

Shield

260 A

Note: Bevel angle range is 0° to 45°.

Metric

English

Select

Gases

Set

Preflow

Set

Cutflow

Minimum

Clearance

Equivalent

Material

thickness

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce

Height

Pierce

Delay

Time

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

Mix

Gas 1

Mix

Gas 2

mm

mm

Range (mm) mm/m mm Factor % Seconds

H35

N

2

12

49

87

60

60

21

2.0

6

4.0 – 10.0

3980

8.0

200

0.3

8

3085

10

2190

12

1790

0.5

15

1650

0.7

20

1320

0.8

40

26

25

920

1.0

32

755

1.2

38

510

Edge start

44

390

50

270

Select

Gases

Set

Preflow

Set

Cutflow

Minimum

Clearance

Equivalent

Material

thickness

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce

Height

Pierce

Delay

Time

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

Mix

Gas 1

Mix

Gas 2

in

in

Range (in)

ipm

in Factor % Seconds

H35

N

2

12

49

87

60

60

21

0.08

1/4

0.16 – 0.40

150

0.32

200

0.3

5/16

121

3/8

90

1/2

65

0.5

5/8

0.7

3/4

55

0.8

40

26

1

35

1.0

1-1/4

30

1.2

1-1/2

20

Edge start

1-3/4

15

2

10

Marking

Select

Gases

Set

Preflow

Set

Cutflow

Amperage Torch-to-Work

Distance

Marking

Speed

Arc

Voltage

Amps

mm

in

mm/m

ipm

Volts

N

2

N

2

10

10

10

10

18

2.5

0.10

6350

250

120

Ar

N

2

30

10

30

10

20

3.0

0.12

2540

100

63

220738

220637

220606

220739

220405

220607

220571

Flow rates – lpm/scfh

H35

N

2

Preflow

0 / 0

132 / 280

Cutflow

13 / 27 163 / 345