10 profibus data exchange – Watson-Marlow Qdos30 User Manual

Page 34

Watson-Marlow qdos30 PROFIBUS Pump User Manual

34

14.10 PROFIBUS data exchange

The data in this section is provided as reference material for a PROFIBUS network

operator. Operating this pump under PROFIBUS control is beyond the scope of this

instruction manual. Consult your PROFIBUS network literature for further information.

Default address: 126

PROFIBUS Ident: 0x0E7D

GSD File: WAMA0E7D.GSD

Config: 0x62, 0x5D (3 words out, 14 words in)

User Parameter bytes: 6

Cyclic Data Write (from Master to pump)

Cyclic Data Write (from Master to pump)

16 bit

Byte 1, 2

Control Word

16 bit

Byte 3, 4

Pumphead Speed Setpoint (unsigned)

16 bit

Byte 5, 6

Set Flow Calibration in μl per revolution

Control Word

Bit

Description

0

Motor running (1= Running)

1

Direction (0= CW, 1= CCW)

2

Tacho Reset (1= Reset Count)

3

Reserved

4

Enable Fieldbus Min/Max Speeds (1= Enabled)

5

Enable Fieldbus Flow Calibration (1= Enabled)

6

Ignore leak detection sensor

7

Fluid Level Reset

8-15

Reserved

Pumphead Speed Setpoint

The speed setpoint is a 16-bit unsigned integer value that represents the speed of

the pump head in 1/10th of RPM. For example 1205 represents 120.5 RPM.

Set Flow Calibration

This parameter is used to set the flow calibration value from the fieldbus interface.

The value is a 16 bit unsigned integer representing μl per revolution. Note that this

value is only used if bit 5 of the Control Word is enabled.

Ignore Leak Detection Sensor

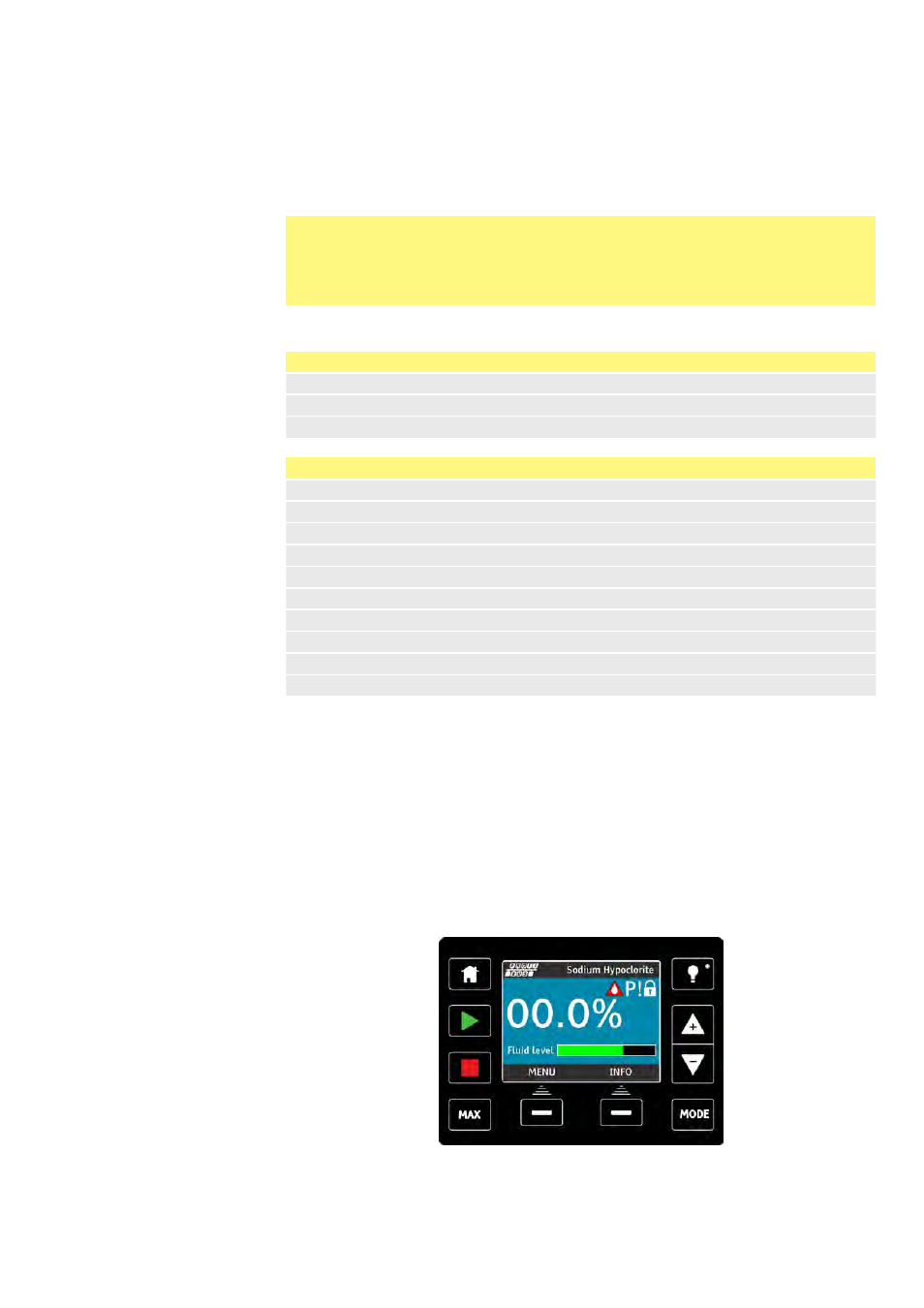

If bit 6 of the control word is enabled, the following run screen will be displayed.