15 start-up and operation, 14 connecting this product to a power supply – Watson-Marlow SPS User Manual

Page 27

MasoSine SPS sinusoidal pumps User Manual

27

15 Start-up and operation

l If you are starting the pump for the first time, or have performed cleaning or

repair work, check first that all screws are correctly and completely tightened.

l The pump may have been contaminated during transport. Remove the pump

front cover and clean if necessary before start-up.

l Before you start the pump, check that the gate and the gate guide are in the

correct orientation in relation to the suction side and the pressure side of the

pump. (See 13.2 Changing rotation direction).

Ensure that the pump is installed in an appropriate

position with all necessary safety guards and

precautions (sensors, switches, pressure gauges, etc).

Observe the appropriate regulations if hazardous fluid is

to be pumped.

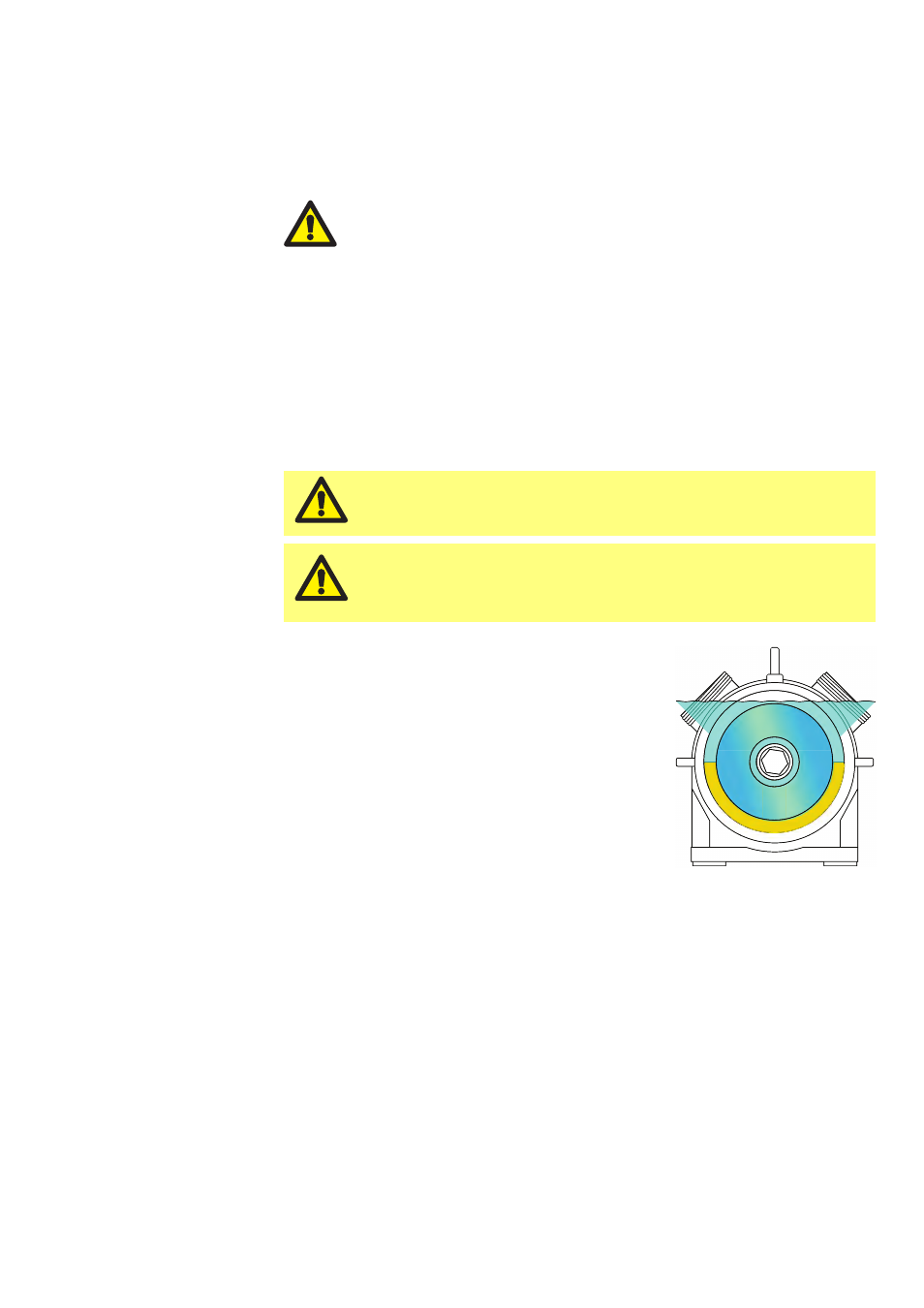

MasoSine pumps must be primed before use.

Before commissioning and during operation, the

pump must be filled with fluid, with the fluid level

above the rotor (see diagram). This can be done

manually through a side channel of your system’s

pipework, or by using a vacuum device where very

viscous fluids are to be pumped; contact MasoSine

for further information. The need to prime can

be avoided by leaving product in the pump after

it is stopped; by leaving CIP or SIP fluid in the

pump after cleaning. For ATEX use, fill the pump

away from potentially explosive atmosphere, and

be aware that if the pump runs dry, the tem-

perature limit for the explosive area may be

exceeded.

Fluid

level

14 Connecting this product

to a power supply

The motor must be connected according to local regulations by a qualified

person. See the instruction manual supplied with your drive motor.