1 simulation mode of operation – HEIDENHAIN CNC Pilot 4290 User Manual

Page 212

5 Graphic Simulation

200

5.1.2

Basics of Operation

How to activate the simulation function

Load the desired NC program.

Set the simulation window (face, surface window,

etc.)

Set the simulations mode (single block, basic block

or without stop)

Select the simulation mode (contour, machining,

motion).

Select ”New.”

Simulation mode ”without stop”:

■

”Stop” stops the the simulation

■

”Continue” resumes the simulation

Simulation mode ”Single block or basic block”:

■

The simulation stops after every single block/

basic block

■

”Continue” resumes the simulation

During a simulation stop you can switch the block

mode, edit the settings or call the dimensioning

function.

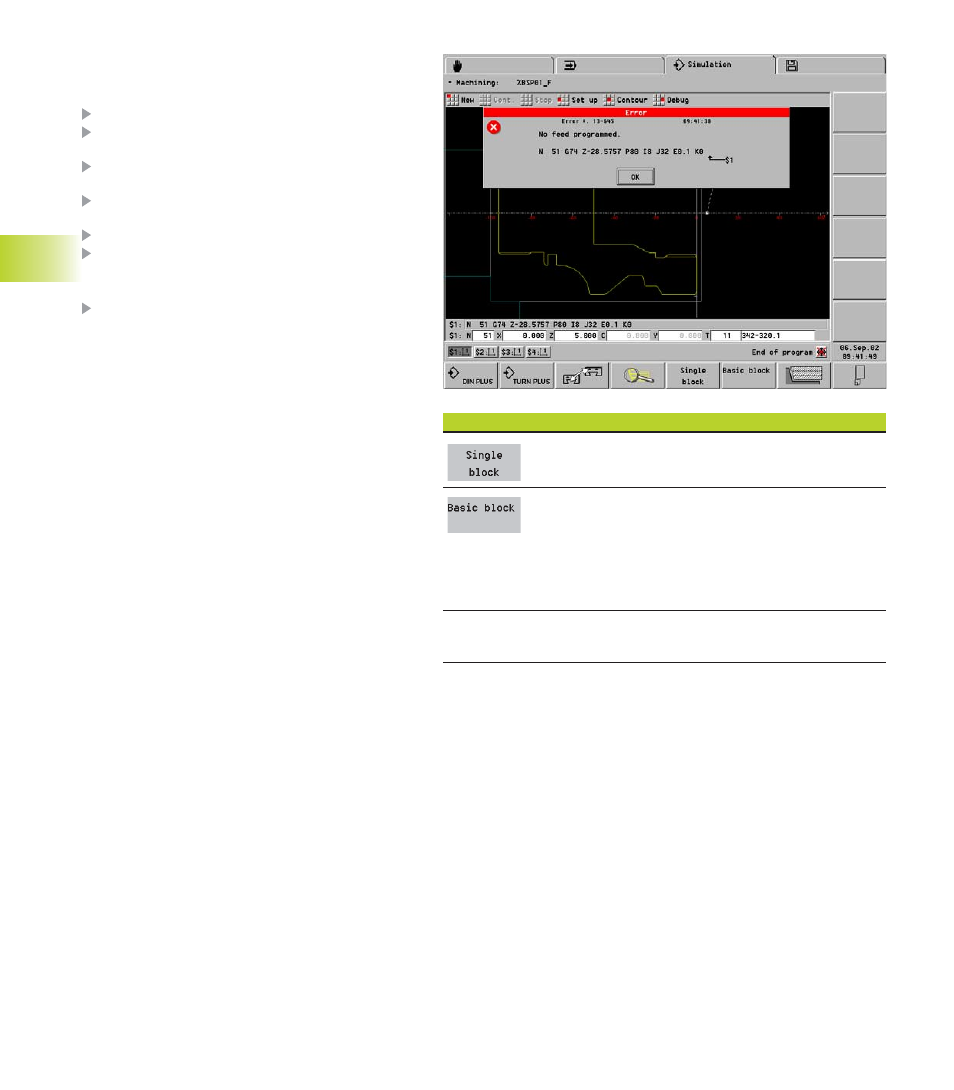

Errors and Warnings

Warnings that occur during the interpretation of an

NC program are displayed in the header. When the

simulation has been stopped or completed, you can

call up the messages by selecting ”Set up -

Warnings.” If more than one warning has occurred,

press ENTER to call up the next message.

The CNC PILOT deletes a warning after you have

confirmed the corresponding message with ENTER.

The system stores a maximum of 20 warnings.

If an error occurs during the interpretation of an NC

program, the simulation is stopped.

5.1 Simulation Mode of Operation

”Set simulation modes” soft keys

Stop after every NC source block. The continue soft key

simulates the next NC source block.

■

Contour simulation: Stop after every contour element.

Contour macros (contour cycles) are ”segmentalized.”

Select ”Continue” to display the next contour element.

■

Machining or motion simulation: Stop after each path

of traverse. Machining cycles are ”segmentalized.” The

continue soft key simulates the next path of traverse.

Without stop (single block and basic block soft keys are not

pressed): The simulation is conducted without stop.