HEIDENHAIN TNC 320 (340 55x-04) Cycle programming User Manual

Page 145

HEIDENHAIN TNC 320

145

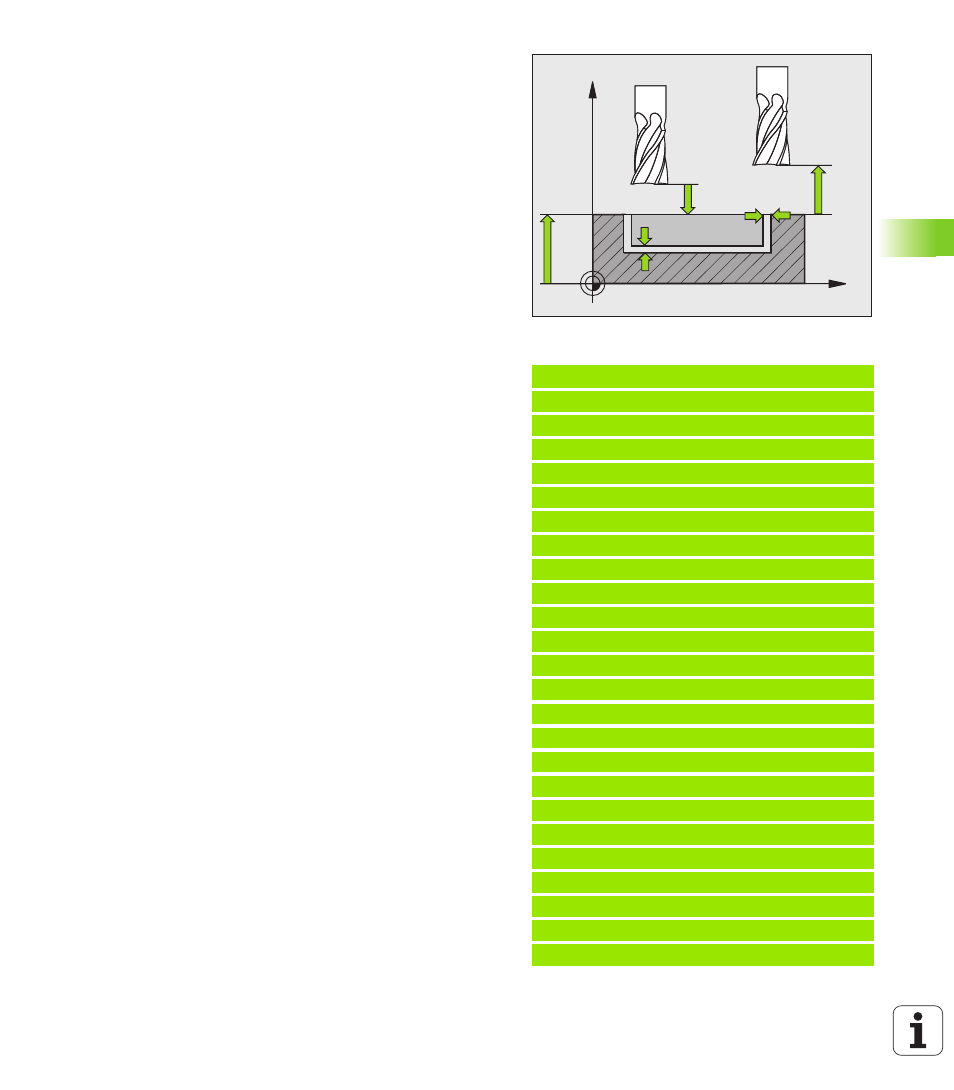

5.5 CIR

C

ULAR SL

O

T

(Cy

c

le 254, DIN/ISO: G254)

U

Setup clearance

Q200 (incremental): Distance

between tool tip and workpiece surface. Input range

0 to 99999.9999

U

Workpiece surface coordinate

Q203 (absolute):

Absolute coordinate of the workpiece surface. Input

range –99999.9999 to 99999.9999

U

2nd setup clearance

Q204 (incremental): Coordinate

in the spindle axis at which no collision between tool

and workpiece (fixtures) can occur. Input range 0 to

99999.9999

U

Plunging strategy

Q366: Type of plunging strategy:

0 = vertical plunging. The TNC plunges

perpendicularly, regardless of the plunging angle

ANGLE

defined in the tool table.

1 = helical plunging. In the tool table, the plunging

angle ANGLE for the active tool must be defined as

not equal to 0. Otherwise, the TNC generates an

error message. Plunge on a helical path only if there

is enough space.

2 = reciprocating plunge. In the tool table, the

plunging angle ANGLE for the active tool must be

defined as not equal to 0. Otherwise, the TNC

generates an error message. The TNC can only

plunge reciprocally once the traversing length on

the circular arc is at least three times the tool

diameter.

U

Feed rate for finishing

Q385: Traversing speed of

the tool during side and floor finishing in mm/min.

Input range: 0 to 99999.999; alternatively FAUTO, FU,

FZ

.

Example: NC blocks

8 CYCL DEF 254 CIRCULAR SLOT

Q215=0

;MACHINING OPERATION

Q219=12

;SLOT WIDTH

Q368=0.2

;ALLOWANCE FOR SIDE

Q375=80

;PITCH CIRCLE DIA.

Q367=0

;REF. SLOT POSITION

Q216=+50

;CENTER IN 1ST AXIS

Q217=+50

;CENTER IN 2ND AXIS

Q376=+45

;STARTING ANGLE

Q248=90

;ANGULAR LENGTH

Q378=0

;STEPPING ANGLE

Q377=1

;NUMBER OF OPERATIONS

Q207=500

;FEED RATE FOR MILLING

Q351=+1

;CLIMB OR UP-CUT

Q201=-20

;DEPTH

Q202=5

;PLUNGING DEPTH

Q369=0.1

;ALLOWANCE FOR FLOOR

Q206=150

;FEED RATE FOR PLUNGING

Q338=5

;INFEED FOR FINISHING

Q200=2

;SETUP CLEARANCE

Q203=+0

;SURFACE COORDINATE

Q204=50

;2ND SETUP CLEARANCE

Q366=1

;PLUNGE

Q385=500

;FEED RATE FOR FINISHING

9 L X+50 Y+50 R0 FMAX M3 M99

X

Z

Q200

Q20

Q20

Q36

Q36