HEIDENHAIN PT 855 for Milling User Manual

Page 69

I - 4 Programming POSITIP

POSITIP 855

Operating Instructions

67

Program section repeats

A program section repeat is entered like a subprogram. The end of

the program section is identified simply by the command to repeat

the section.

Label 0 is therefore not set.

Display of the

CALL LBL

block with a program section repeat

The screen displays (for example):

CALL LBL 1 REP 10 / 10

.

The two numbers with the slash between them indicate that this is

a program section repeat. The number in front of the slash is the

number of repeats you entered. The number behind the slash is

the number of repeats remaining to be performed.

Subprograms and program section repeats

Example: Insert a label for a program section repeat

Operating mode:

PROGRAMMING AND EDITING

Go to the second soft key row.

Select

Edit

.

Set a program mark (

LBL

) for a program section repeat.

POSITIP offers the lowest available label number as a default.

/

L a b e l n u m b e r ?

ENT

1

ENT

Enter a label number (here, 1). Confirm your entry.

The current block now contains the set label:

LBL 1

.

Accept the default label number.

Enter the blocks for the program section repeat after the

LBL

block.

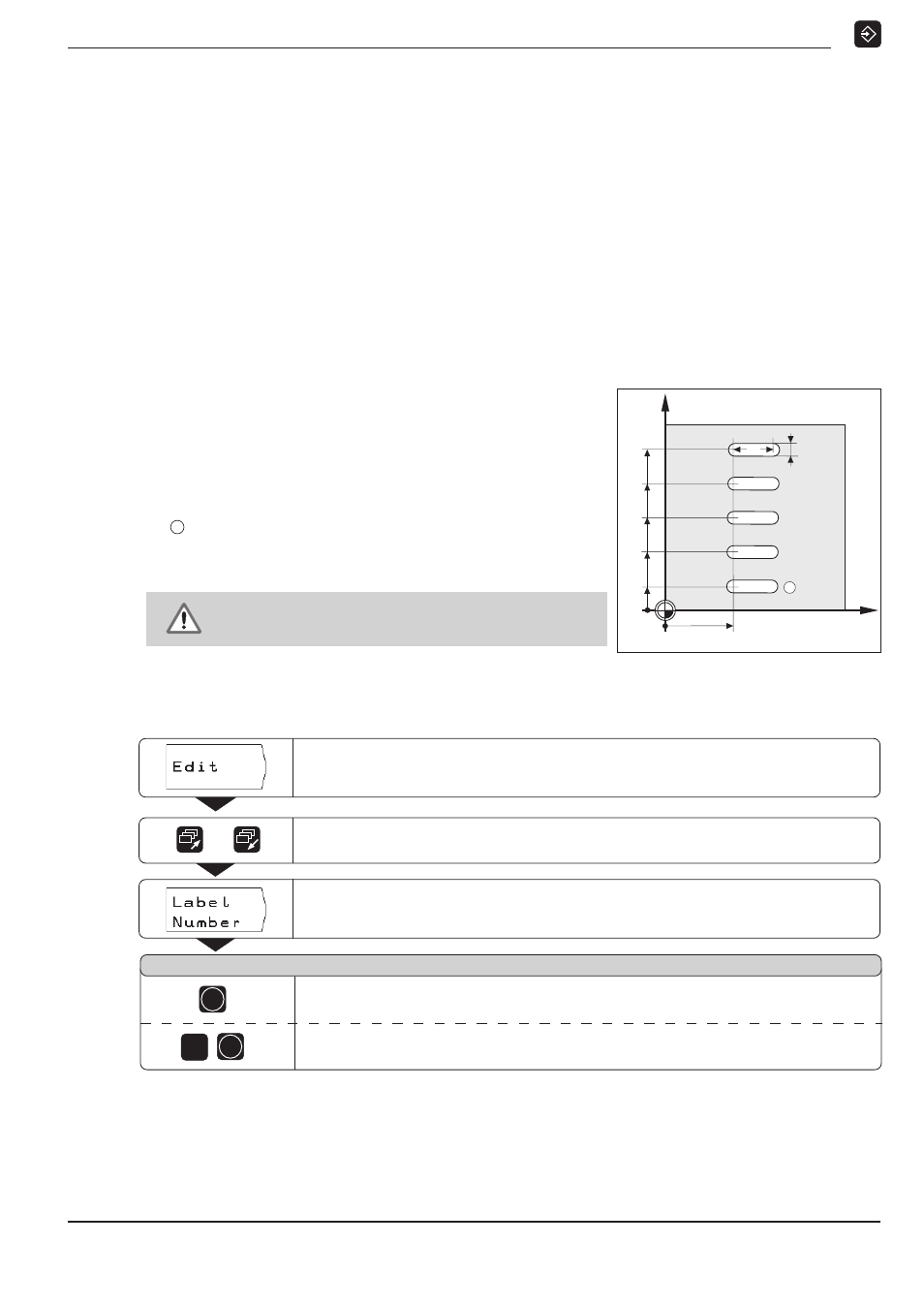

Programming example: Program section repeat for slots

Slot length:

16 mm +tool diameter

Slot depth:

12 mm

Incremental offset of the

recess point:

15 mm

Slot diameter:

6 mm (= tool diameter)

Coordinates of the recess point

Slot

:

X = 30 mm Y = 10 mm

A center-cut end mill (DIN 844)

is required for carrying out this example!

Y

X

70

0

0

30

55

10

6

40

25

16

1

1