Cycle run – HEIDENHAIN TNC 640 (34059x-02) Cycle programming User Manual

Page 206

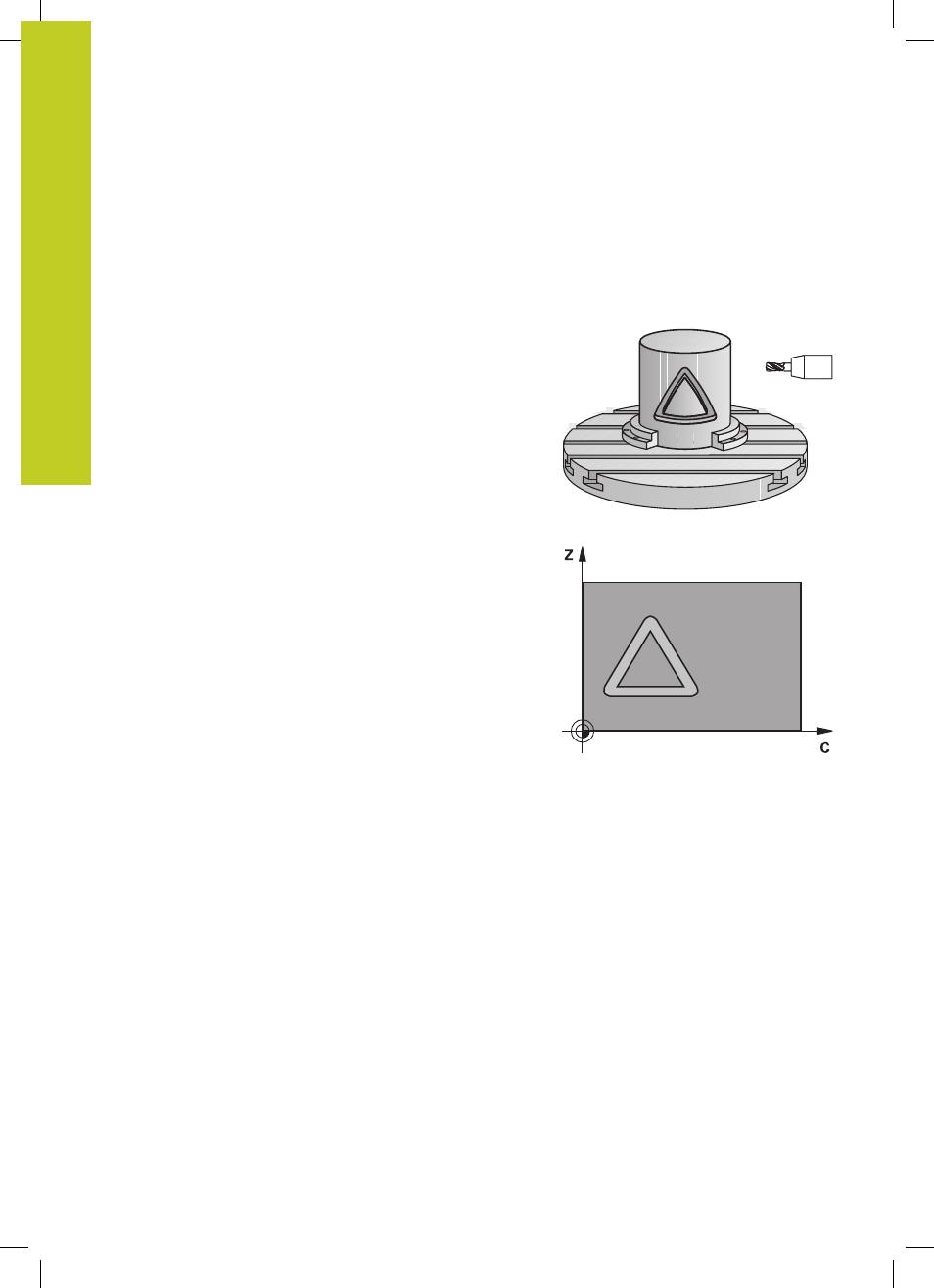

Fixed Cycles: Cylindrical Surface

8.3

CYLINDER SURFACE Slot milling (Cycle 28, DIN/ISO: G128,

software option 1)

8

206

TNC 640 | User's Manual Cycle Programming | 5/2013

8.3

CYLINDER SURFACE Slot milling

(Cycle 28, DIN/ISO: G128, software

option 1)

Cycle run

This cycle enables you to program a guide notch in two dimensions

and then transfer it onto a cylindrical surface. Unlike Cycle 27,

with this cycle the TNC adjusts the tool so that, with radius

compensation active, the walls of the slot are nearly parallel. You

can machine exactly parallel walls by using a tool that is exactly as

wide as the slot.

The smaller the tool is with respect to the slot width, the larger the

distortion in circular arcs and oblique line segments. To minimize

this process-related distortion, you can define in parameter Q21

a tolerance with which the TNC machines a slot as similar as

possible to a slot machined with a tool of the same width as the

slot.

Program the midpoint path of the contour together with the tool

radius compensation. With the radius compensation you specify

whether the TNC cuts the slot with climb milling or up-cut milling.

1 The TNC positions the tool over the cutter infeed point.

2 At the first plunging depth, the tool mills along the programmed

slot wall at the milling feed rate Q12 while respecting the

finishing allowance for the side.

3 At the end of the contour, the TNC moves the tool to the

opposite wall and returns to the infeed point.

4 Steps 2 to 3 are repeated until the programmed milling depth

Q1 is reached.

5 If you have defined the tolerance in Q21, the TNC then

remachines the slot walls to be as parallel as possible.

6 Finally, the tool retracts in the tool axis to the clearance height

or to the position last programmed before the cycle.