Please note while programming, Cycle parameters – HEIDENHAIN TNC 640 (34059x-02) Cycle programming User Manual

Page 364

Cycles: Turning

13.25 AXIAL RECESSING

(Cycle 871, DIN/ISO: G871)

13

364

TNC 640 | User's Manual Cycle Programming | 5/2013

Please note while programming:

Program a positioning block to the starting position

with radius compensation

R0 before the cycle call.

The tool position at cycle call defines the size of the

area to be machined (cycle starting point).

Cycle parameters

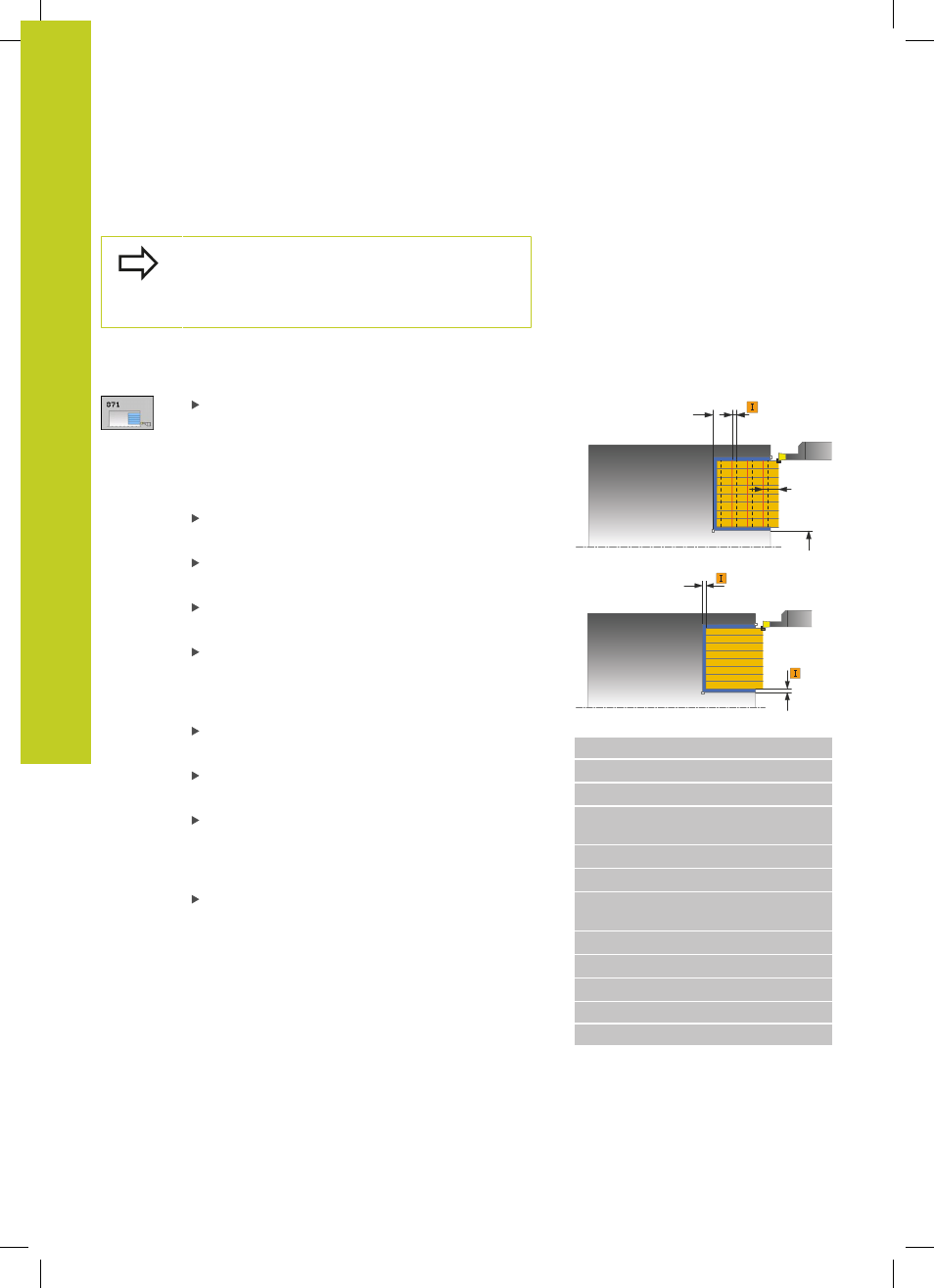

Machining operation Q215: Define machining

operation:

0

: Roughing and finishing

1

: Only roughing

2

: Only finishing to finished dimension

3

: Only finishing to oversize

Set-up clearance Q460: Reserved, currently

without function

Diameter at end of contour Q493: X coordinate of

the contour end point (diameter value)

Contour end in Z Q494: Z coordinate of the contour

end point

Roughing feed rate Q478: Feed rate during

roughing. If M136 has been programmed, the

value is interpreted by the TNC in millimeters per

revolution, without M136 in millimeters per minute.

Oversize in diameter Q483 (incremental): Diameter

oversize for the defined contour

Oversize in Z Q484 (incremental): Oversize for the

defined contour in axial direction

Finishing feed rate Q505: Feed rate during

finishing. If M136 has been programmed, the

value is interpreted by the TNC in millimeters per

revolution, without M136 in millimeters per minute.

Limit to depth Q463: Max. recess depth per cut

Q460

Ø Q493

Q494

Q463

Ø Q483

Q484

NC blocks

11 CYCL DEF 871 AXIAL RECESSING

Q215=+0

;MACHINING OPERATION

Q460=+2

;SAFETY CLEARANCE

Q493=+50

;DIAMETER AT END OF

CONTOUR

Q494=-10

;CONTOUR END IN Z

Q478=+0.3

;ROUGHING FEED RATE

Q483=+0.4

;OVERSIZE FOR

DIAMETER

Q484=+0.2

;OVERSIZE IN Z

Q505=+0.2

;FINISHING FEED RATE

Q463=+0

;LIMIT TO DEPTH

12 L X+65 Y+0 Z+2 FMAX M303

13 CYCL CALL