Cycle parameters – HEIDENHAIN TNC 640 (34059x-02) Cycle programming User Manual

Page 313

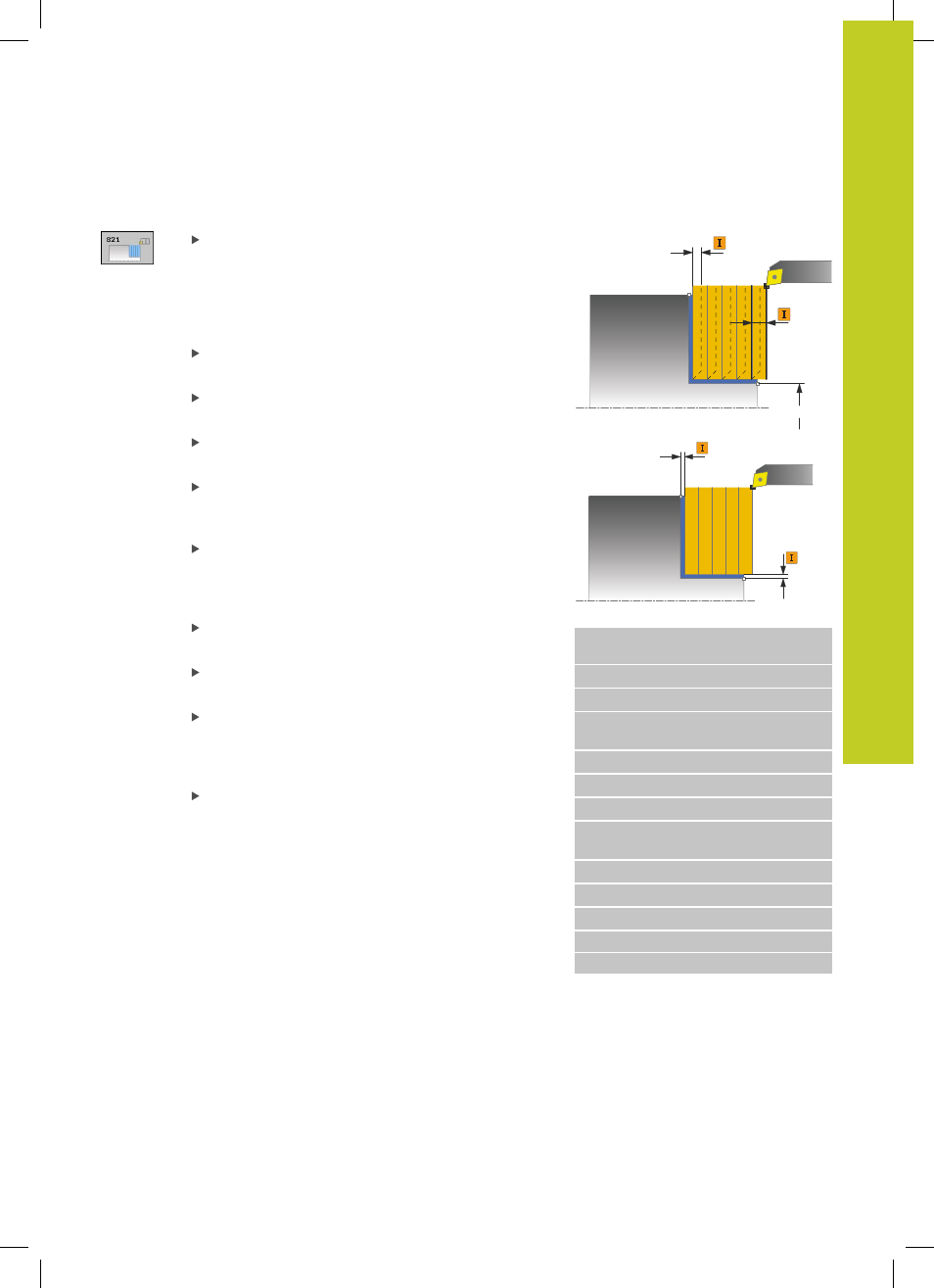

TURN SHOULDER FACE

(Cycle 821, DIN/ISO: G821)

13.11

13

TNC 640 | User's Manual Cycle Programming | 5/2013

313

Cycle parameters

Machining operation Q215: Define machining

operation:

0

: Roughing and finishing

1

: Only roughing

2

: Only finishing to finished dimension

3

: Only finishing to oversize

Set-up clearance Q460 (incremental): Distance for

retraction and pre-positioning

Diameter at end of contour Q493: X coordinate of

the contour end point (diameter value)

Contour end in Z Q494: Z coordinate of the contour

end point

Maximum cutting depth Q463: Maximum infeed in

axial direction. The infeed is divided evenly to avoid

abrasive cuts.

Roughing feed rate Q478: Feed rate during

roughing. If M136 has been programmed, the

value is interpreted by the TNC in millimeters per

revolution, without M136 in millimeters per minute.

Oversize in diameter Q483 (incremental): Diameter

oversize for the defined contour

Oversize in Z Q484 (incremental): Oversize for the

defined contour in axial direction

Finishing feed rate Q505: Feed rate during

finishing. If M136 has been programmed, the

value is interpreted by the TNC in millimeters per

revolution, without M136 in millimeters per minute.

Contour smoothing Q506:

0

: After each cut along the contour (within the

infeed range)

1

: Contour smoothing after the last cut (complete

contour); retract below 45°

2

: No contour smoothing; retract below 45°

Q460

Ø Q493

Q463

Ø Q483

Q484

NC blocks

11 CYCL DEF 821 TURN SHOULDER

FACE

Q215=+0

;MACHINING OPERATION

Q460=+2

;SAFETY CLEARANCE

Q493=+30

;DIAMETER AT END OF

CONTOUR

Q494=-5

;CONTOUR END IN Z

Q463=+3

;MAX. CUTTING DEPTH

Q478=+0.3

;ROUGHING FEED RATE

Q483=+0.4

;OVERSIZE FOR

DIAMETER

Q484=+0.2

;OVERSIZE IN Z

Q505=+0.2

;FINISHING FEED RATE

Q506=+0

;CONTOUR SMOOTHING

12 L X+75 Y+0 Z+2 FMAX M303

13 CYCL CALL