HEIDENHAIN iTNC 530 (340 49x-04) ISO programming User Manual

Page 357

HEIDENHAIN iTNC 530

357

8.3 Cy

cles f

o

r Dr

illing, T

a

pping and Thr

ead Milling

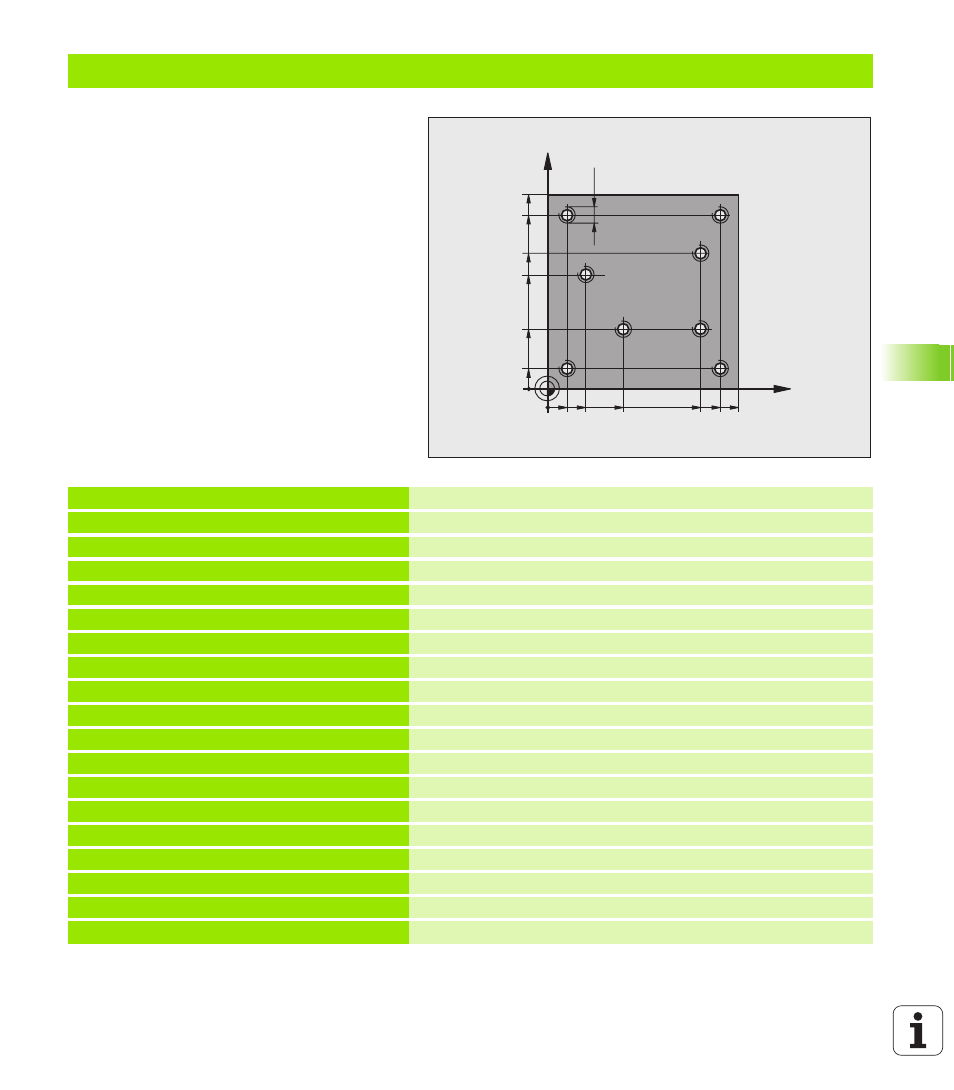

Example: Calling drilling cycles in connection with point tables

The drill hole coordinates are stored in the point

table TAB1.PNT and are called by the TNC with

G79 PAT.

The tool radii are selected so that all work steps

can be seen in the test graphics.

Program sequence

Centering

Drilling

Tapping

%1 G71 *

N10 G30 G17 X+0 Y+0 Z-20 *

Definition of workpiece blank

N20 G31 G90 X+100 Y+100 Z+0 *

N30 G99 T1 L+0 R+4 *

Tool definition of center drill

N40 G99 T2 L+0 R+2.4 *

Define tool: drill

N50 G99 T3 L+0 R+3 *

Tool definition of tap

N60 T1 G17 S5000 *

Tool call of centering drill

N70 G01 G40 Z+10 F5000 *

Move tool to clearance height (Enter a value for F.

The TNC positions to the clearance height after every cycle.)

N80 %:PAT: “TAB1“ *

Defining point tables

N90 G200 DRILLING

Cycle definition: CENTERING

Q200=2

;SET-UP CLEARANCE

Q201=-2

;DEPTH

Q206=150

;FEED RATE FOR PLNGNG

Q202=2

;PLUNGING DEPTH

Q210=0

;DWELL TIME AT TOP

Q203=+0

;SURFACE COORDINATE

0 must be entered here, effective as defined in point table

Q204=0

;2ND SET-UP CLEARANCE

0 must be entered here, effective as defined in point table

Q211=0.2

;DWELL TIME AT DEPTH

X

Y

20

10

100

100

10

90

90

80

30

55

40

65

M6