2 fundamentals of path functions, Programming tool movements for workpiece machining – HEIDENHAIN iTNC 530 (606 42x-02) User Manual

Page 215

HEIDENHAIN iTNC 530

215

6.2 F

undamentals of P

a

th F

unctions

6.2 Fundamentals of Path

Functions

Programming tool movements for workpiece

machining

You create a part program by programming the path functions for the

individual contour elements in sequence. You usually do this by

entering the coordinates of the end points of the contour

elements given in the production drawing. The TNC calculates the

actual path of the tool from these coordinates, and from the tool data

and radius compensation.

The TNC moves all axes programmed in a single block simultaneously.

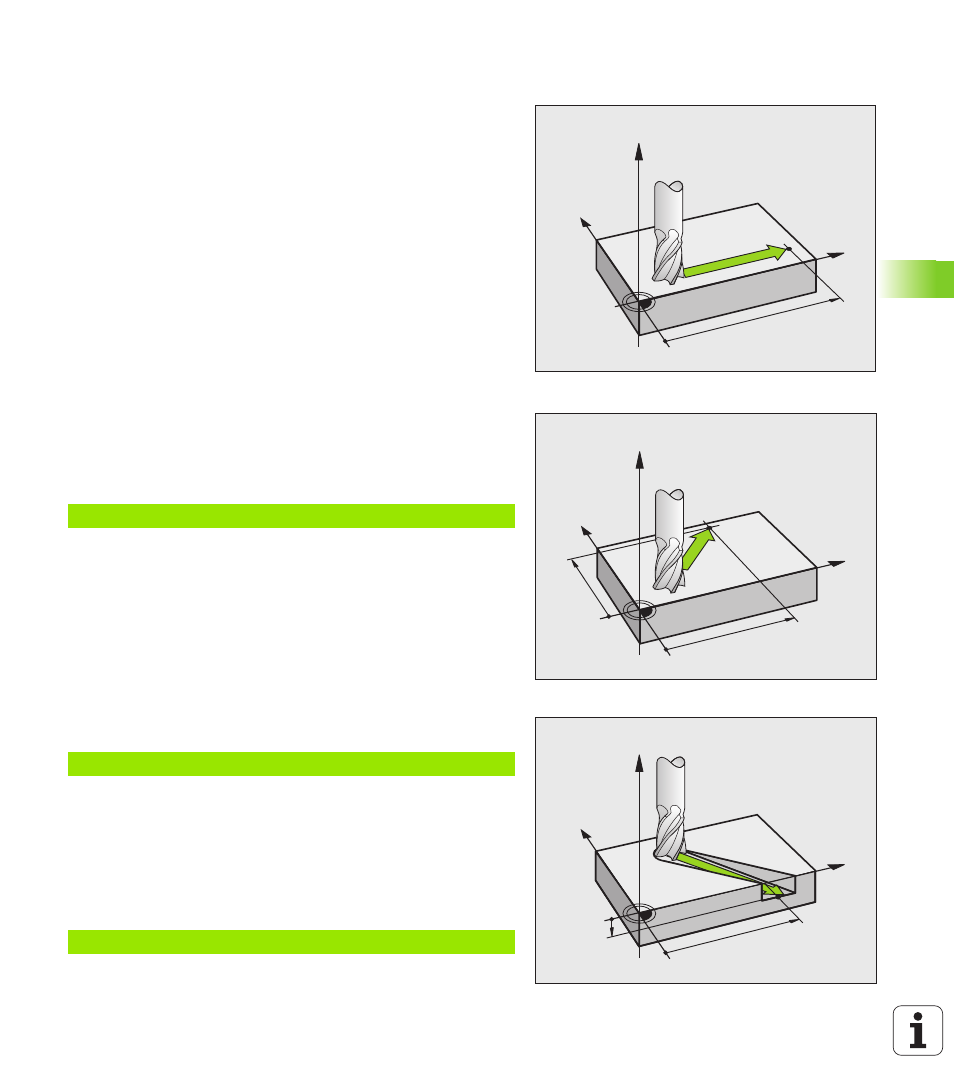

Movement parallel to the machine axes

The program block contains only one coordinate. The TNC thus moves

the tool parallel to the programmed axis.

Depending on the individual machine tool, the part program is

executed by movement of either the tool or the machine table on

which the workpiece is clamped. Nevertheless, you always program

path contours as if the tool were moving and the workpiece remaining

stationary.

Example:

The tool retains the Y and Z coordinates and moves to the position

X=100. See figure.

Movement in the main planes

The program block contains two coordinates. The TNC thus moves the

tool in the programmed plane.

Example:

The tool retains the Z coordinate and moves in the XY plane to the

position X=70, Y=50 (see figure).

Three-dimensional movement

The program block contains three coordinates. The TNC thus moves

the tool in space to the programmed position.

Example:

X

Y

Z

100

50 L X+100

50

Block number

L

Path function “straight line at ”

X+100

Coordinate of the end point

X

Y

Z

70

50

L X+70 Y+50

X

Y

Z

80

-10

L X+80 Y+0 Z-10