HEIDENHAIN iTNC 530 (606 42x-02) User Manual

Page 535

HEIDENHAIN iTNC 530

535

13.2 P

a

llet Oper

ation with T

ool-Or

ient

e

d Mac

h

ining

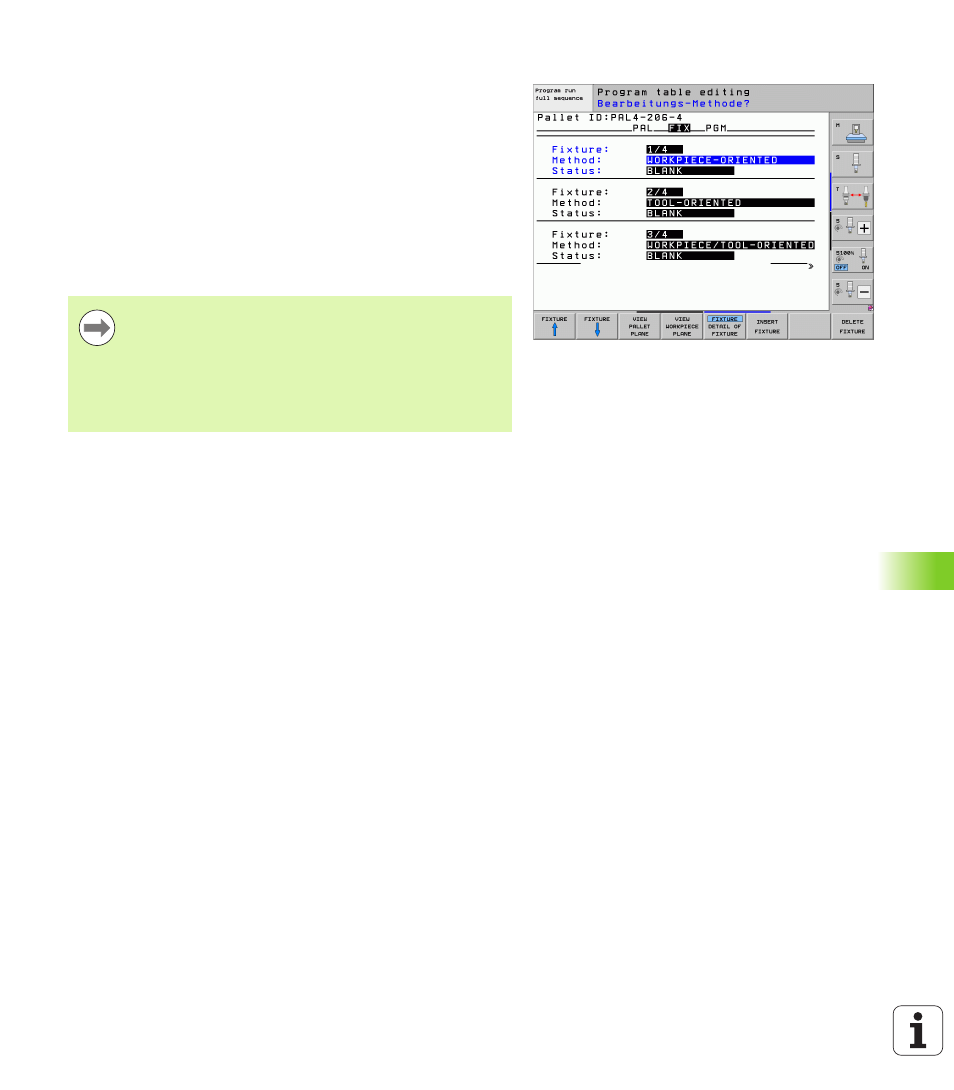

Setting up the fixture level

Fixture:

The number of the fixture is displayed. The number of

fixtures within this level is shown after the slash.

Method:

You can choose between the WORKPIECE ORIENTED and the

TOOL ORIENTED

machining methods. The selected method is

assumed for the workpiece level and overwrites any existing

entries. In tabular view, WORKPIECE ORIENTED appears as WPO and

TOOL ORIENTED

appears as TO.

Use the CONNECT/SEPARATE soft key to mark fixtures that are to be

included for calculating the machining process for tool-oriented

machining. Connected fixtures are indicated by a dashed line,

whereas separated fixtures are indicated by a solid line. Connected

workpieces are marked in tabular view with the entry CTO in the

METHOD column.

Status:

The soft key BLANK identifies the fixture and the

corresponding workpieces as not yet having been machined, and

enters BLANK in the Status field. Use the EMPTY POSITION or OMIT

soft key if you want to skip the fixture during machining. EMPTY or

SKIP

appears in the status field.

The TOOL/WORKPIECE ORIENTED entry cannot be made via

soft key. It only appears when different machining

methods were chosen for the workpieces in the

workpiece level.

If the machining method was determined in the fixture

level, the entries are transferred to the workpiece level,

where they overwrite any existing entries.