3 fixture monitoring (dcm software option), Fundamentals – HEIDENHAIN iTNC 530 (606 42x-02) User Manual

Page 403

HEIDENHAIN iTNC 530

403

1

1

.3 Fixt

ur

e Monit

o

ri

ng (DCM

Sof

tw

a

re

Option)

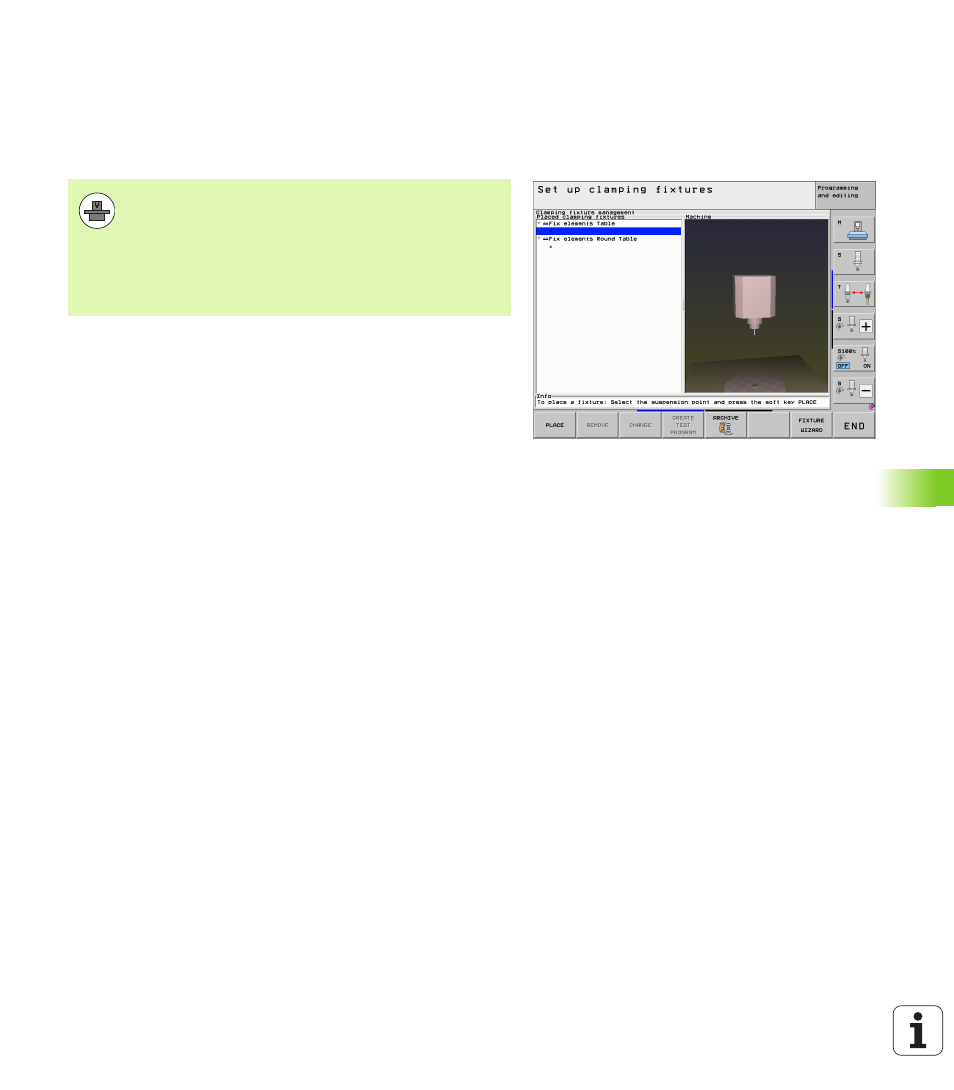

11.3 Fixture Monitoring

(DCM Software Option)

Fundamentals

Using the fixture management in the Manual operating mode, you can

place simple fixtures in the working space of the machine in order to

implement collision monitoring between the tool and the fixture.

Several work steps are required to place fixtures

Model the fixture template

On its Web site, HEIDENHAIN provides fixture templates such as

vises or jaw chucks in a fixture template library (see “Fixture

templates” on page 404), that were created with the PC program

KinematicsDesign. The machine tool builder can model additional

fixture templates and provide you with them. The fixture templates

have the file name extension cft

Set the fixture parameter values: FixtureWizard

With the FixtureWizard you define the exact dimensions of the

fixture by entering parameters values in the fixture template. The

FixtureWizard is available as a component of the TNC fixture

management. It generates a placeable fixture with concrete

dimensions defined by you, (see “Setting parameter values for the

fixture: FixtureWizard” on page 404). Placable fixture templates

have the file name extension cfx

Place the fixture on the machine

In an interactive menu the TNC guides you through the actual

measurement process. The measurement process consists

essentially of the performance of various probing functions on the

fixture and entering variable sizes, for example the jaw gap of a vise

(see “Placing the fixture on the machine” on page 406)

Check the position of the measured fixture

After you have placed the fixture, you can have the TNC create a

measuring program as needed with which you can have the actual

position of the placed fixture compared with the nominal position. If

the deviations between the nominal and actual positions are too

large, the TNC issues an error message (see “Check the position of

the measured fixture” on page 408)

Your machine tool builder must define permissible

location points in the kinematic description before you can

use the fixture monitoring. The machine tool manual

provides further information.

Your machine has to feature a 3-D touch probe for

workpiece measurement. Otherwise you cannot locate

the fixture on the machine.