Cycle parameters – HEIDENHAIN TNC 640 (34059x-01) Cycle programming User Manual

Page 131

HEIDENHAIN TNC 640

131

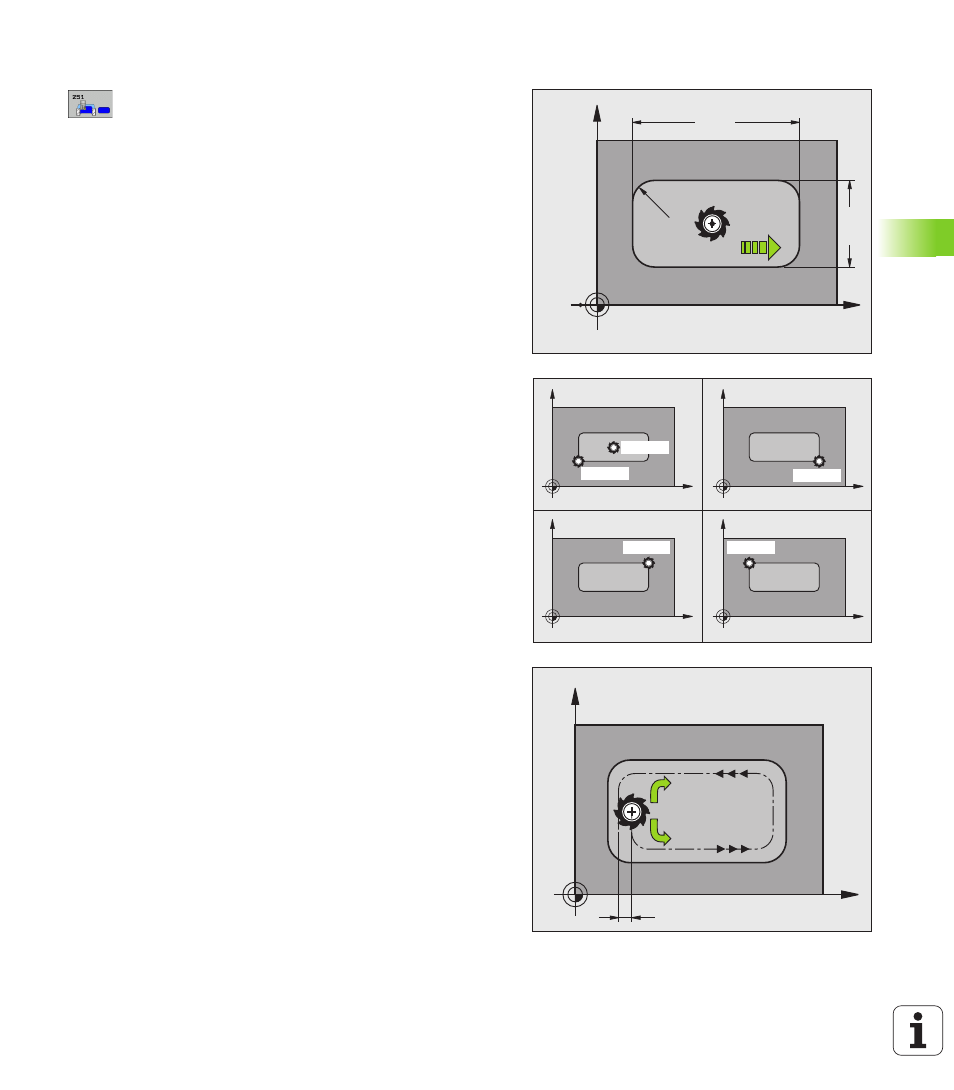

5.2 RECT

ANGULAR POCKET (Cy

c

le

251, DIN/ISO: G251)

Cycle parameters

U

Machining operation (0/1/2)

Q215: Define the

machining operation:

0: Roughing and finishing

1: Only roughing

2: Only finishing

Side finishing and floor finishing are only executed if

the finishing allowances (Q368, Q369) have been

defined.

U

1st side length

Q218 (incremental): Pocket length,

parallel to the reference axis of the working plane.

Input range 0 to 99999.9999

U

2nd side length

Q219 (incremental): Pocket length,

parallel to the minor axis of the working plane. Input

range 0 to 99999.9999

U

Corner radius

Q220: Radius of the pocket corner. If

you have entered 0 here, the TNC assumes that the

corner radius is equal to the tool radius. Input range 0

to 99999.9999

U

Finishing allowance for side

Q368 (incremental):

Finishing allowance in the working plane. Input range

0 to 99999.9999

U

Angle of rotation

Q224 (absolute): Angle by which

the entire pocket is rotated. The center of rotation is

the position at which the tool is located when the

cycle is called. Input range -360.0000 to 360.0000

U

Pocket position

Q367: Position of the pocket in

reference to the position of the tool when the cycle is

called:

0: Tool position = Center of pocket

1: Tool position = Lower left corner

2: Tool position = Lower right corner

3: Tool position = Upper right corner

4: Tool position = Upper left corner

U

Feed rate for milling

Q207: Traversing speed of the

tool during milling in mm/min. Input range 0 to

99999.999; alternatively FAUTO, FU, FZ

U

Climb or up-cut

Q351: Type of milling operation with

M3:

+1 = climb milling

–1 = up-cut milling

X

Y

Q21

9

Q218

Q207

Q220

X

Y

X

Y

X

Y

X

Y

Q367=0

Q367=1

Q367=2

Q367=3

Q367=4

X

Y

k

Q351= +1

Q351= 1