11 measure coordinate (cycle 427, din/iso: g427), Cycle run, Please note while programming – HEIDENHAIN TNC 640 (34059x-01) Cycle programming User Manual

Page 488

488

Touch Probe Cycles: Automatic Workpiece Inspection

1

7.1

1 MEA

S

URE COORDINA

TE

(Cy

c

le

427

, DIN/ISO: G427)

17.11 MEASURE COORDINATE

(Cycle 427, DIN/ISO: G427)

Cycle run

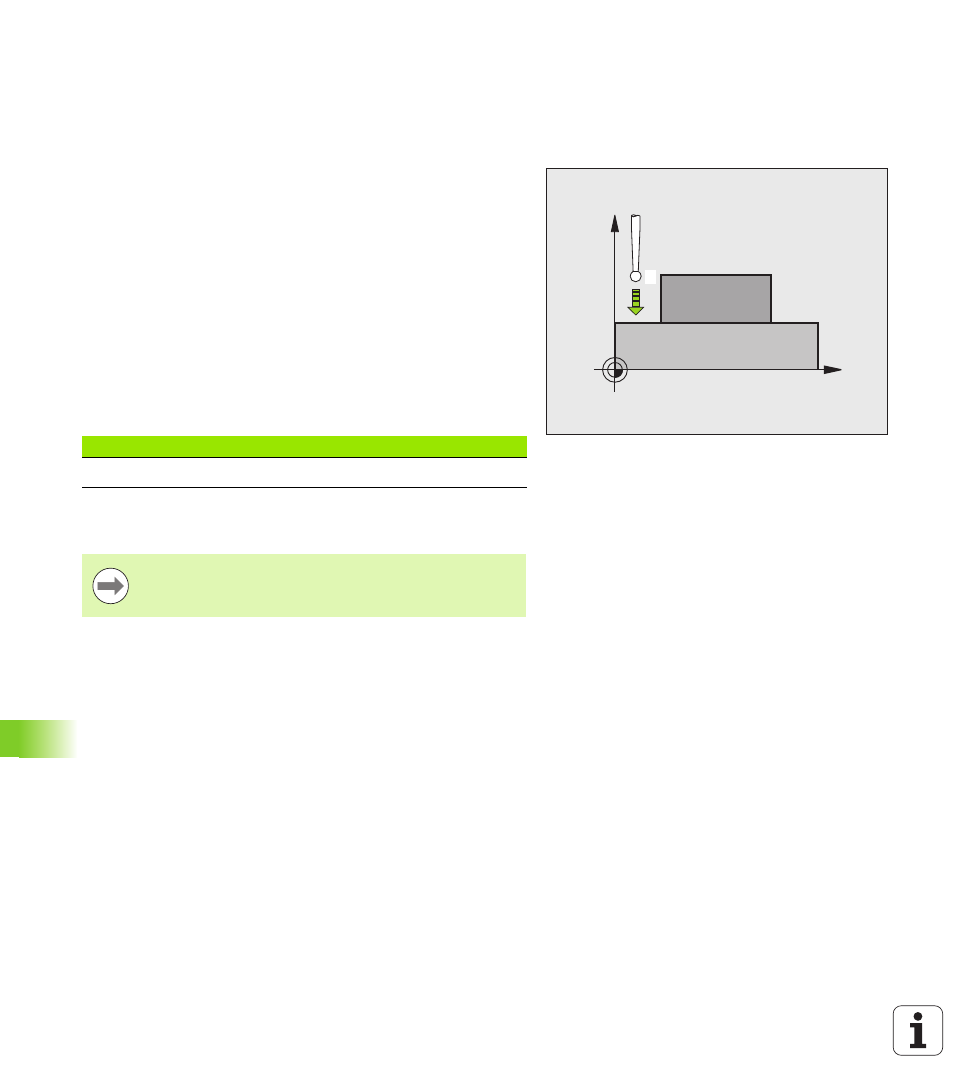

Touch Probe Cycle 427 finds a coordinate in a selectable axis and

saves the value in a system parameter. If you define the

corresponding tolerance values in the cycle, the TNC makes a

nominal-to-actual value comparison and saves the deviation value in

system parameters.

1

The TNC positions the touch probe at rapid traverse (value from

FMAX

column) following the positioning logic (see "Executing touch

probe cycles" on page 373) to the starting point

1

. The TNC offsets

the touch probe by the safety clearance in the direction opposite

the defined traverse direction.

2

Then the TNC positions the touch probe to the entered touch point

1

in the working plane and measures the actual value in the

selected axis.

3

Finally the TNC returns the touch probe to the clearance height and

saves the measured coordinate in the following Q parameter:

Please note while programming:

X

Z

1

Parameter number

Meaning

Q160

Measured coordinate

Before a cycle definition you must have programmed a

tool call to define the touch probe axis.