Cycle run, Please note while programming – HEIDENHAIN TNC 640 (34059x-01) Cycle programming User Manual

Page 389

HEIDENHAIN TNC 640

389

15.5 BA

SIC R

O

T

A

TION Compensation via Rotary Axis (Cy

c

le 403,

DIN/ISO:

G403)

15.5 BASIC ROTATION

Compensation via Rotary Axis

(Cycle 403, DIN/ISO: G403)

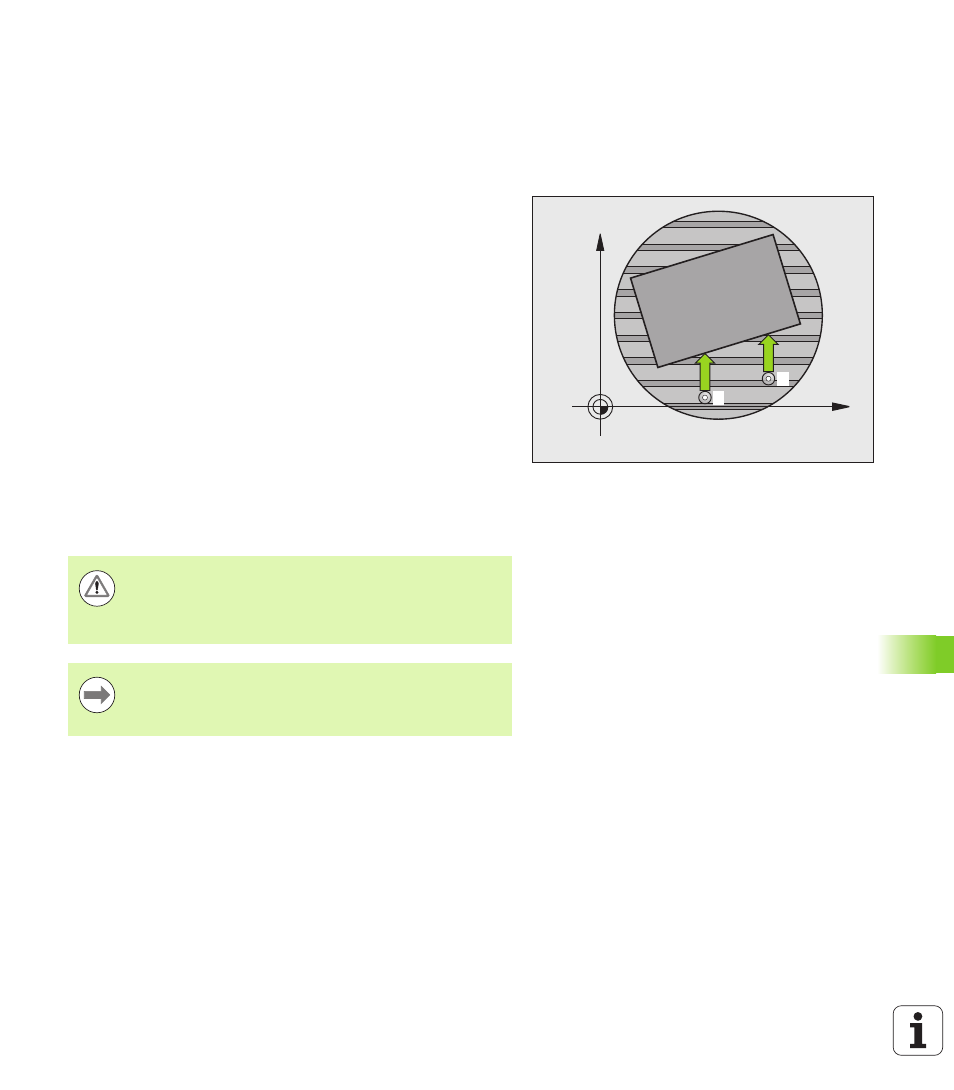

Cycle run

Touch Probe Cycle 403 determines a workpiece misalignment by

measuring two points, which must lie on a straight surface. The TNC

compensates the determined misalignment by rotating the A, B or C

axis. The workpiece can be clamped in any position on the rotary table.

1

The TNC positions the touch probe at rapid traverse (value from

FMAX

column) following the positioning logic (see "Executing touch

probe cycles" on page 373) to the programmed starting point

1

.

The TNC offsets the touch probe by the safety clearance in the

direction opposite the defined traverse direction.

2

Then the touch probe moves to the entered measuring height and

probes the first touch point at the probing feed rate (column F).

3

Then the touch probe moves to the next starting position

2

and

probes the second position.

4

The TNC returns the touch probe to the clearance height and

moves the rotary axis, which was defined in the cycle, by the

measured value. Optionally you can have the display set to 0 after

alignment.

Please note while programming:

X

Y

1

2

Danger of collision!

The TNC does not check whether touch points and

compensation axis match. This can result in compensation

movements offset by 180°.

Before a cycle definition you must have programmed a

tool call to define the touch probe axis.

The TNC stores the measured angle in parameter Q150.