Please note while programming, Cycle parameters – HEIDENHAIN TNC 640 (34059x-01) Cycle programming User Manual

Page 237

HEIDENHAIN TNC 640

237

1

0

.4 F

A

CE MILLING (Cy

c

le 232, DIN/ISO: G232)

Please note while programming:

Cycle parameters

U

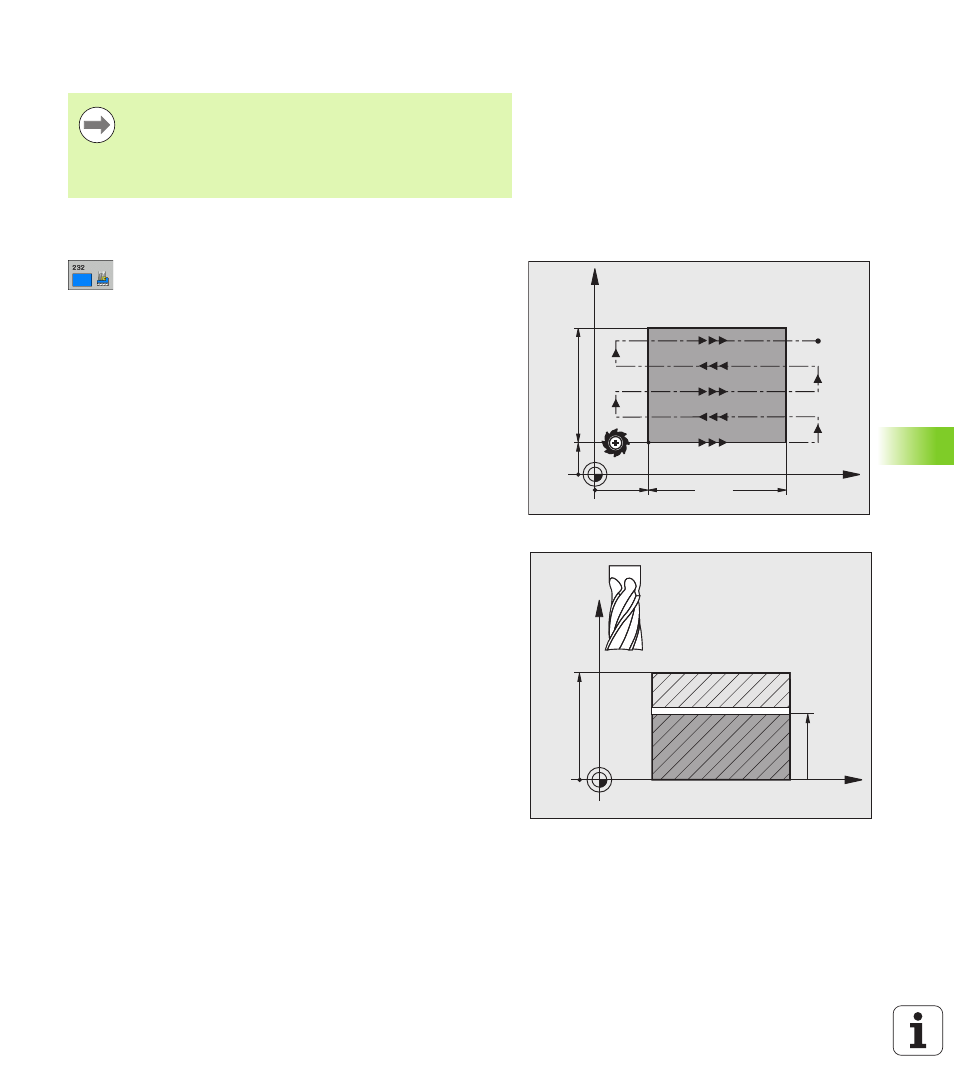

Machining strategy (0/1/2)

Q389: Specify how the

TNC is to machine the surface:

0: Meander machining, stepover at positioning feed

rate outside the surface to be machined

1: Meander machining, stepover at feed rate for

milling within the surface to be machined

2: Line-by-line machining, retraction and stepover at

the positioning feed rate

U

Starting point in 1st axis

Q225 (absolute): Starting

point coordinate of the surface to be machined in the

reference axis of the working plane. Input range

-99999.9999 to 99999.9999

U

Starting point in 2nd axis

Q226 (absolute): Starting

point coordinate of the surface to be multipass-milled

in the minor axis of the working plane. Input range

-99999.9999 to 99999.9999

U

Starting point in 3rd axis

Q227 (absolute):

Coordinate of the workpiece surface used to calculate

the infeeds. Input range -99999.9999 to 99999.9999

U

End point in 3rd axis

Q386 (absolute): Coordinate

in the spindle axis to which the surface is to be face

milled. Input range -99999.9999 to 99999.9999

U

1st side length

Q218 (incremental value): Length of

the surface to be machined in the reference axis of

the working plane. Use the algebraic sign to specify

the direction of the first milling path in reference to

the starting point in the 1st axis. Input range

-99999.9999 to 99999.9999

U

2nd side length

Q219 (incremental value): Length of

the surface to be machined in the minor axis of the

working plane. Use the algebraic sign to specify the

direction of the first stepover in reference to the

starting point in the 2nd axis

. Input range

-99999.9999 to 99999.9999

Enter the 2nd set-up clearance in Q204 such that no

collision with the workpiece or the fixtures can occur.

If the starting point in the 3rd axis Q227 and the end point

in the 3rd axis Q386 are entered as equal values, the TNC

does not run the cycle (depth = 0 has been programmed).

X

Y

Q226

Q225

Q21

9

Q218

X

Z

Q227

Q386