Cycle parameters – HEIDENHAIN TNC 640 (34059x-01) Cycle programming User Manual

Page 446

446

Touch Probe Cycles: Automatic Datum Setting

16.13 D

A

TUM IN ONE AXIS (C

y

c

le

41

9, DIN/ISO: G41

9

)

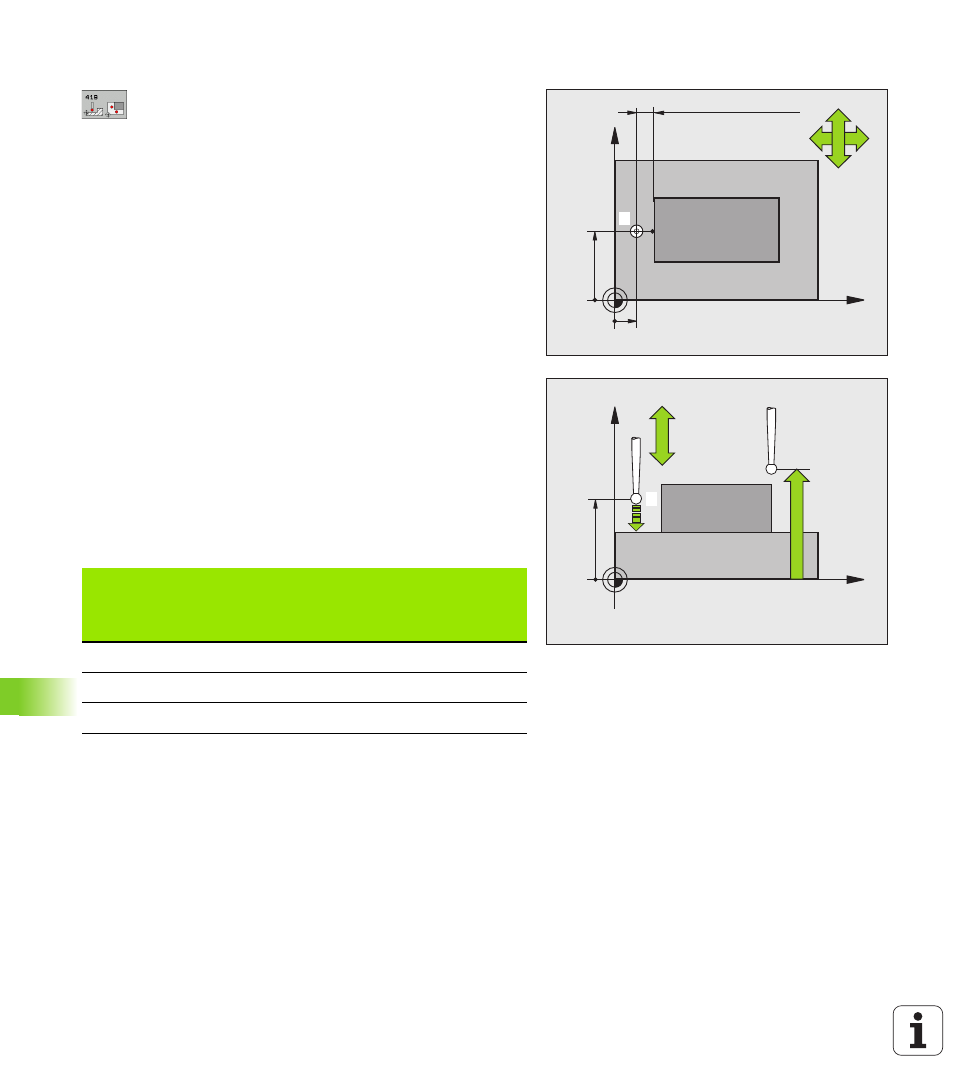

Cycle parameters

U

1st meas. point 1st axis

Q263 (absolute):

Coordinate of the first touch point in the reference

axis of the working plane. Input range -99999.9999 to

99999.9999

U

1st meas. point 2nd axis

Q264 (absolute):

Coordinate of the first touch point in the minor axis of

the working plane. Input range -99999.9999 to

99999.9999

U

Measuring height in the touch probe axis

Q261

(absolute): Coordinate of the ball tip center (= touch

point) in the touch probe axis in which the

measurement is to be made. Input range

-99999.9999 to 99999.9999

U

Set-up clearance

Q320 (incremental): Additional

distance between measuring point and ball tip. Q320

is added to SET_UP (touch probe table). Input range 0

to 99999.9999

U

Clearance height

Q260 (absolute): Coordinate in the

touch probe axis at which no collision between touch

probe and workpiece (fixtures) can occur. Input range

-99999.9999 to 99999.9999

U

Measuring axis (1...3: 1=reference axis)

Q272:

Axis in which the measurement is to be made:

1: Reference axis = measuring axis

2: Minor axis = measuring axis

3: Touch probe axis = measuring axis

X

Y

Q264

Q263

+

+

Q267

Q272=2

Q272=1

1

SET_UP(TCHPROBE.TP)

+Q320

X

Z

Q260

Q261

+

Q272=1

Q272=3

Q267

1

Axis assignment

Active touch probe

axis: Q272= 3

Corresponding

reference axis:

Q272 = 1

Corresponding

minor axis:

Q272 = 2

Z

X

Y

Y

Z

X

X

Y

Z