9 measure inside width (cycle 425, din/iso: g425), Cycle run, Please note while programming – HEIDENHAIN TNC 640 (34059x-01) Cycle programming User Manual

Page 482

482

Touch Probe Cycles: Automatic Workpiece Inspection

1

7.9 MEA

S

URE INSIDE WIDTH (Cy

c

le 425, DIN/ISO: G425)

17.9

MEASURE INSIDE WIDTH

(Cycle 425, DIN/ISO: G425)

Cycle run

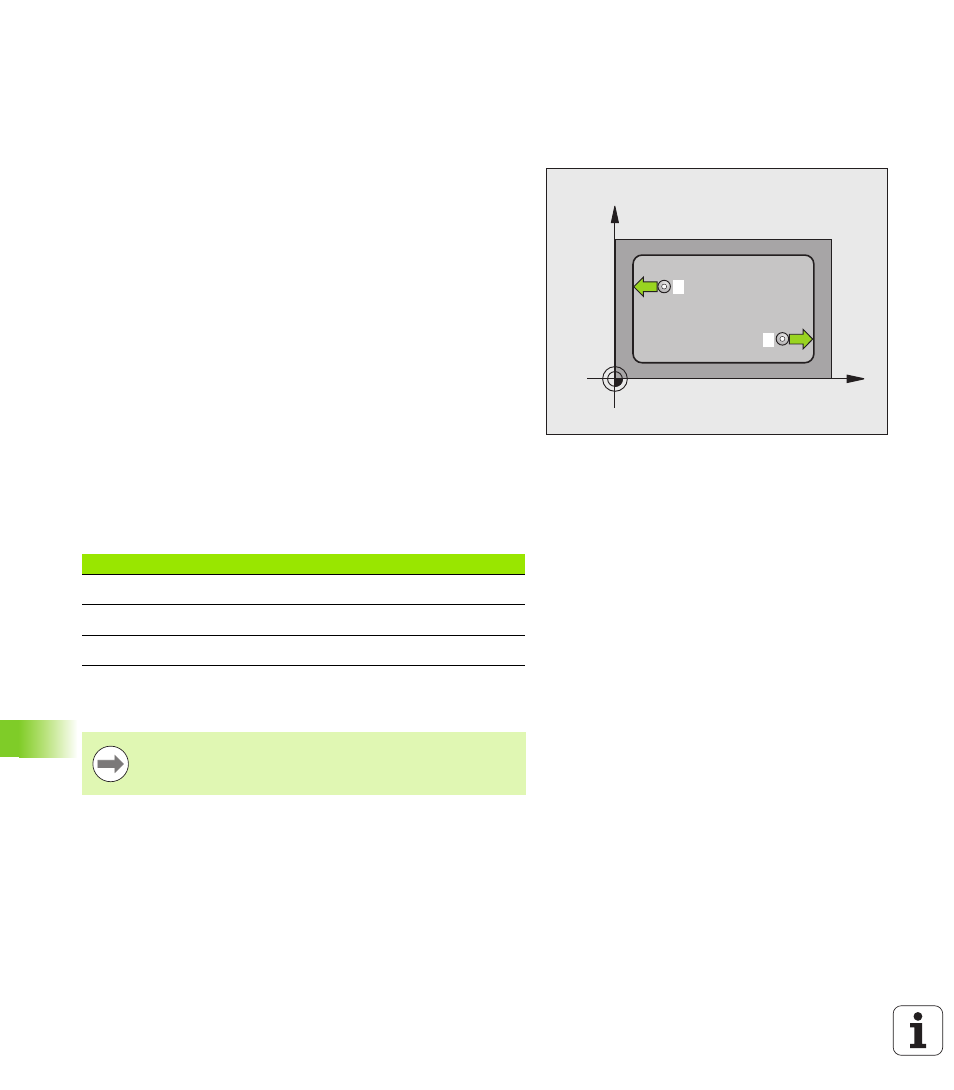

Touch Probe Cycle 425 measures the position and width of a slot (or

pocket). If you define the corresponding tolerance values in the cycle,

the TNC makes a nominal-to-actual value comparison and saves the

deviation value in a system parameter.

1

The TNC positions the touch probe at rapid traverse (value from

FMAX

column) following the positioning logic (see "Executing touch

probe cycles" on page 373) to the starting point

1

. The TNC

calculates the touch points from the data in the cycle and the

safety clearance from the SET_UP column of the touch probe table.

2

Then the touch probe moves to the entered measuring height and

probes the first touch point at the probing feed rate (column F). The

first probing is always in the positive direction of the programmed

axis.

3

If you enter an offset for the second measurement, the TNC then

moves the touch probe (if required, at clearance height) to the next

starting point

2

and probes the second touch point. If the nominal

length is large, the TNC moves the touch probe to the second

touch point at rapid traverse. If you do not enter an offset, the TNC

measures the width in the exact opposite direction.

4

Finally the TNC returns the touch probe to the clearance height and

saves the actual values and the deviation in the following

Q parameters:

Please note while programming:

X

Y

1

2

Parameter number

Meaning

Q156

Actual value of measured length

Q157

Actual value of the centerline

Q166

Deviation of the measured length

Before a cycle definition you must have programmed a

tool call to define the touch probe axis.