5 p a th cont ours—p o lar coor dinat e s – HEIDENHAIN iTNC 530 (340 49x-01) ISO programming User Manual

Page 198

198

6 Programming: Programming Contours

6.5 P

a

th Cont

ours—P

o

lar Coor

dinat

e

s

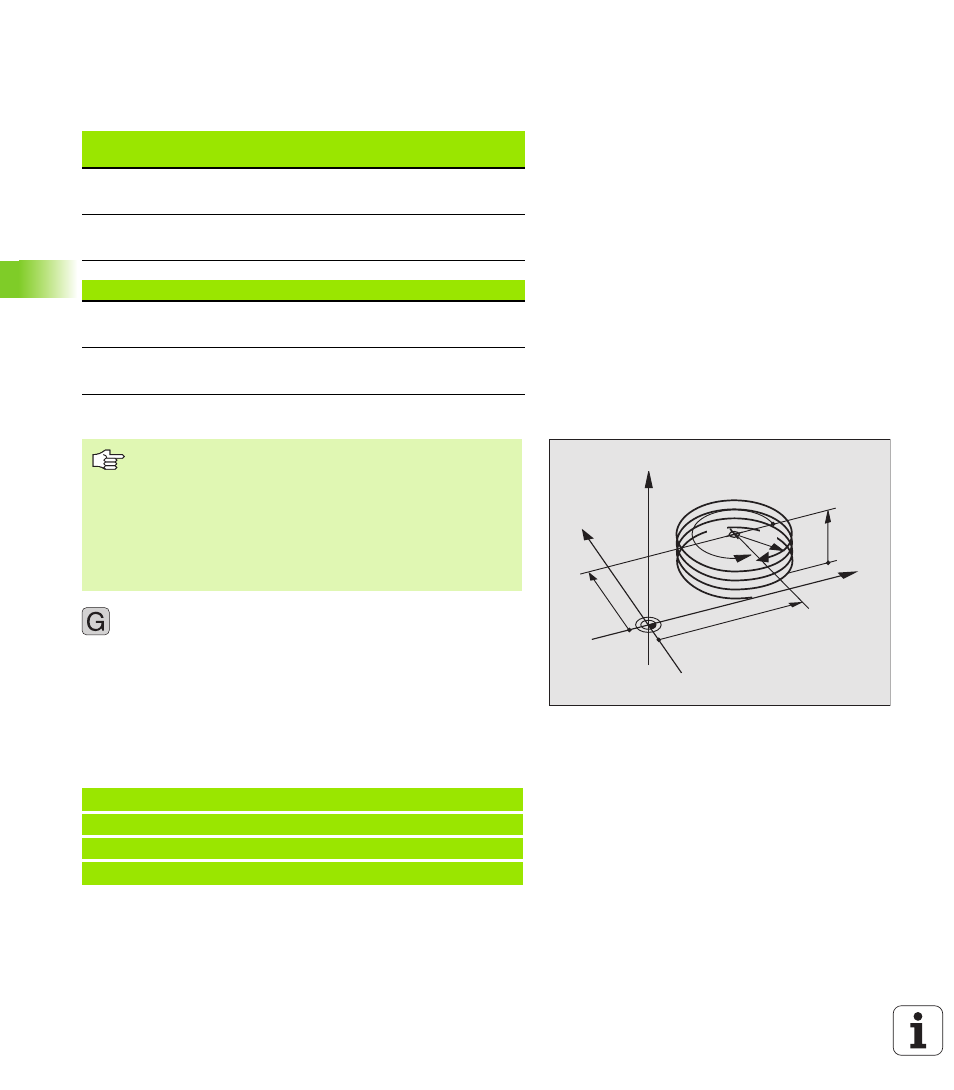

Shape of the helix

The table below illustrates in which way the shape of the helix is

determined by the work direction, direction of rotation and radius

compensation.

Programming a helix

8

Polar coordinates angle H: Enter the total angle of tool

traverse along the helix in incremental dimensions.

After entering the angle, specify the tool axis with

an axis selection key.

8

Enter the coordinate for the height of the helix in

incremental dimensions.

8

Enter the radius compensation G41/G42 according to

the table above.

Example NC blocks: Thread M6 x 1 mm with 5 revolutions

Internal thread

Work

direction

Direction

Radius

comp.

Right-handed

Left-handed

Z+

Z+

G13

G12

G41

G42

Right-handed

Left-handed

Z–

Z–

G12

G13

G42

G41

External thread

Right-handed

Left-handed

Z+

Z+

G13

G12

G42

G41

Right-handed

Left-handed

Z–

Z–

G12

G13

G41

G42

Always enter the same algebraic sign for the direction of

rotation and the incremental total angle G91 H. The tool

may otherwise move in a wrong path and damage the

contour.

For the total angle G91 H, you can enter a value from

–5400° to +5400°. If the thread has more than 15

revolutions, program the helix in a program section repeat

(see “Program Section Repeats” on page 418)

N120 I+40 J+25 *

N130 G01 Z+0 F100 M3 *

N140 G11 G41 R+3 H+270 *

N150 G12 G91 H-1800 Z+5 *

Y

X

Z

25

40

5

270°

R3

CC

12