HEIDENHAIN iTNC 530 (340 49x-01) ISO programming User Manual

Page 305

HEIDENHAIN iTNC 530

305

8.4 Cy

cles f

o

r Milling P

o

c

k

ets, St

uds and Slots

8

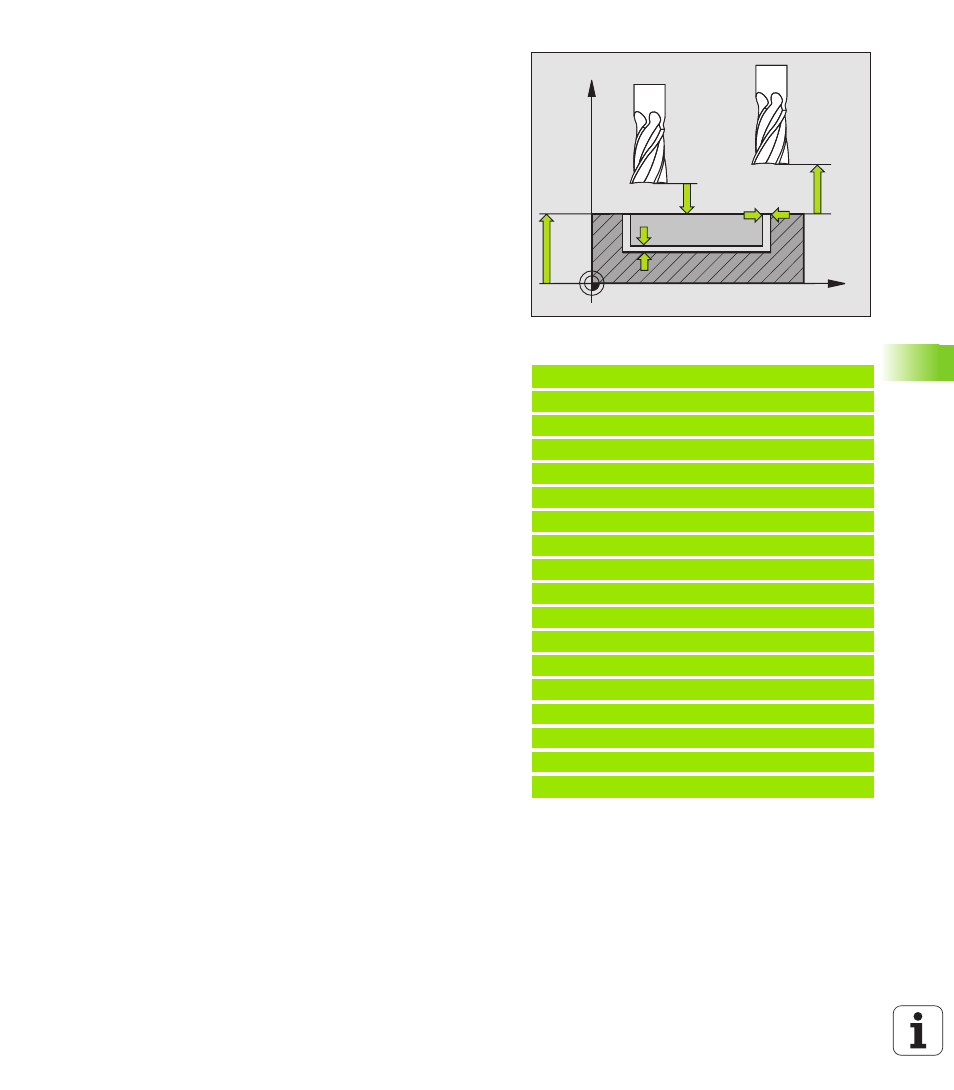

Set-up clearance

Q200 (incremental value): Distance

between tool tip and workpiece surface.

8

Workpiece surface coordinate

Q203 (absolute

value): Absolute coordinate of the workpiece surface

8

2nd set-up clearance

Q204 (incremental value):

Coordinate in the tool axis at which no collision

between tool and workpiece (clamping devices) can

occur.

8

Path overlap factor

Q370: Q370 x tool radius =

stepover factor k.

8

Plunging strategy

Q366: Type of plunging strategy.

0 = vertical plunging. In the tool table, the plunging

angle ANGLE for the active tool must be defined as

90°. Otherwise the TNC displays an error message.

1 = helical plunging. In the tool table, the plunging

angle ANGLE for the active tool must be defined not

equal to 0. Otherwise the TNC displays an error

message.

8

Feed rate for finishing

Q385: Traversing speed of

the tool during side and floor finishing in mm/min.

Example: NC blocks

N10 G252 CIRCULAR POCKET

Q215=0

;MACHINING OPERATION

Q223=60

;CIRCLE DIAMETER

Q368=0.2

;ALLOWANCE FOR SIDE

Q207=500

;FEED RATE FOR MILLING

Q351=+1

;CLIMB OR UP-CUT

Q201=-20

;DEPTH

Q202=5

;PLUNGING DEPTH

Q369=0.1

;ALLOWANCE FOR FLOOR

Q206=150

;FEED RATE FOR PLNGNG

Q338=5

;INFEED FOR FINISHING

Q200=2

;SET-UP CLEARANCE

Q203=+0

;SURFACE COORDINATE

Q204=50

;2ND SET-UP CLEARANCE

Q370=1

;TOOL PATH OVERLAP

Q366=1

;PLUNGING

Q385=500

;FEED RATE FOR FINISHING

N20 G79:G01 X+50 Y+50 Z+0 F15000 M3

X

Z

Q200

Q204

Q203

Q369

Q368