10 .1 0 pr ogr amming examples, Example: convex sphere machined with end mill – HEIDENHAIN iTNC 530 (340 49x-01) ISO programming User Manual

Page 460

460

10 Programming: Q Parameters

1

0

.1

0 Pr

ogr

amming Examples

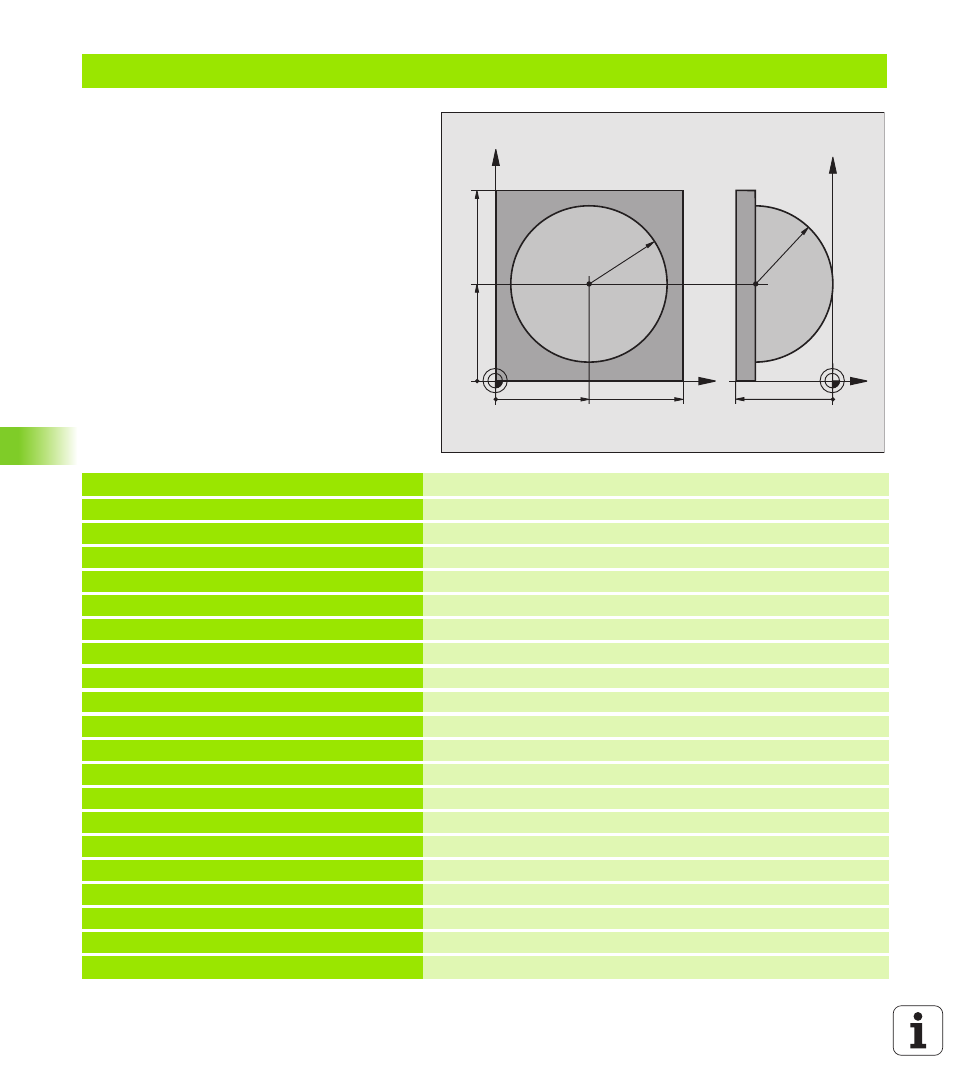

Example: Convex sphere machined with end mill

Program sequence

This program requires an end mill.

The contour of the sphere is approximated by

many short lines (in the Z/X plane, defined in

Q14). The smaller you define the angle

increment, the smoother the curve becomes.

You can determine the number of contour cuts

through the angle increment in the plane

(defined in Q18).

The tool moves upward in three-dimensional

cuts.

The tool radius is compensated automatically.

%SPHERE G71 *

N10 D00 Q1 P01 +50 *

Center in X axis

N20 D00 Q2 P01 +50 *

Center in Y axis

N30 D00 Q4 P01 +90 *

Starting angle in space (Z/X plane)

N40 D00 Q5 P01 +0 *

End angle in space (Z/X plane)

N50 D00 Q14 P01 +5 *

Angle increment in space

N60 D00 Q6 P01 +45 *

Radius of the sphere

N70 D00 Q8 P01 +0 *

Starting angle of rotational position in the X/Y plane

N80 D00 Q9 P01 +360 *

End angle of rotational position in the X/Y plane

N90 D00 Q18 P01 +10 *

Angle increment in the X/Y plane for roughing

N100 D00 Q10 P01 +5 *

Allowance in sphere radius for roughing

N110 D00 Q11 P01 +2 *

Set-up clearance for pre-positioning in the tool axis

N120 D00 Q12 P01 +350 *

Feed rate for milling

N130 G30 G17 X+0 Y+0 Z-50 *

Define the workpiece blank

N140 G31 G90 X+100 Y+100 Z+0 *

N150 G99 T1 L+0 R+7.5 *

Define the tool

N160 T1 G17 S4000 *

Tool call

N170 G00 G40 G90 Z+250 *

Retract the tool

N180 L10.0 *

Call machining operation

N190 D00 Q10 P01 +0 *

Reset allowance

N200 D00 Q18 P01 +5 *

Angle increment in the X/Y plane for finishing

X

Y

50

100

100

Z

Y

-50

R45

50

R45